Fishermark

Vice Admiral

- Joined

- Oct 19, 2003

- Messages

- 5,617

Don't use just any kind of pump to remove fuel from the tank. Your messing with gas and explosions can happen.

Fuel pumps are shielded from sparks and pumps like water pumps are not. We just got to know you and we don't want to be reading about you in the papers or on TV. We have a lot more teasing to do before were done

If you don't have an electric fuel pump use a siphon type pump and hose

I was a little concerned too at first when I read where someone said something about a bilge pump.... As I re-read the posts, I believe the point is to make sure the OP has a good bilge pump on an auto switch to help ensure that the boat doesn't get full of water. NOT to pump the gas out. But yes, it is good to make sure everyone is on the same page on this issue.

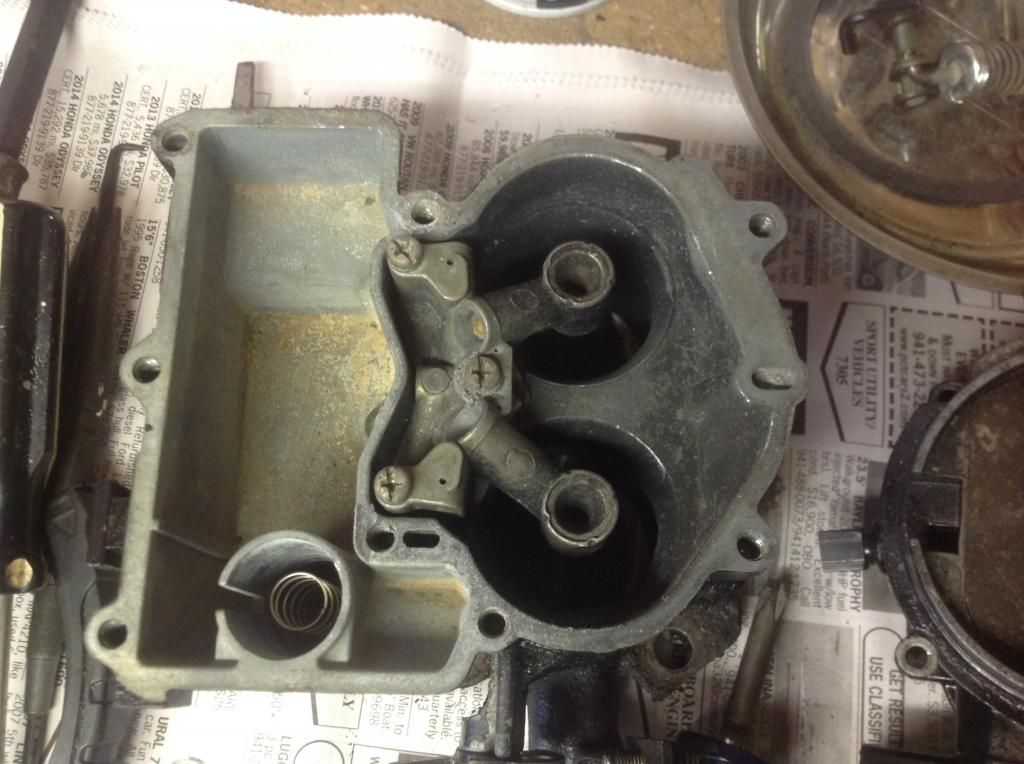

Back to the carb - I still think your best best is to take it apart. I'm not talking complete rebuild - simply taking the top off and using a rag to clean out the bowl. That simple. If you don't feel confident doing that, maybe you have a friend who can help. I wouldn't waste money on the additives to absorb water - most are nothing more than alcohol anyway.