mikezohsix

Petty Officer 2nd Class

- Joined

- Oct 26, 2009

- Messages

- 111

I needed to figure out how much floatation to put into my Grumman I/O that I?ve been redoing. I read the USCG rules, but found that the answer wasn?t there, at least in a way that helped me when I was standing in the insulation aisle at HD.

So I did some math, that I thought I?d share with others, that is pretty practical.

May seem like one of those math quizzes, but it does work?

Fresh water weighs 62.4 pounds per cubic ft, so one cubic foot of foam will float 62.4 pounds. (I?m not going to consider the weight of the foam in these calculations because it would have a minimal impact.)

So, if I want to know how much foam I need to float my 3.0 OMC I/O setup, the first thing I need to know is how much the drive train weighs. I asked here, and a got a couple of different answers, but the average estimate seems to be about 650 pounds.

How many cu ft of foam would I need? 650/62.4 = 10.4 cubic feet.

What do you do with the 10.4 cubic feet?

A 2? thick x 24? wide x 8? (96?) long foam board is 4608 cu in.

Divide cu in by 1728 to get cubic feet.

4608/1728 = 2.7 cubic feet per board.

To get to the needed 10.4 cubic feet, you need 10.4/2.7, or 3.9, which rounds up to four 2? boards

So, 4 two inch boards will float by drive train.

I guessed that the rest of the aluminum boat weighs in at 400 pounds.

To float 400 pounds I need 400/62.4 = 6.4 cubic feet of foam

6.4/2.7 = 2.3, so I need another two and a third 2? boards, for a total of 6.3, to float the whole boat.

Now 2? foam won?t fit everywhere, so here?s the numbers for the other foam boards at HD.

2? thick is 2.7 cu ft per board

1.5 inch thick is 2.0 cu ft per board

1 inch thick is 1.3 cu ft per board

? inch thick is 1.0 cu ft per board.

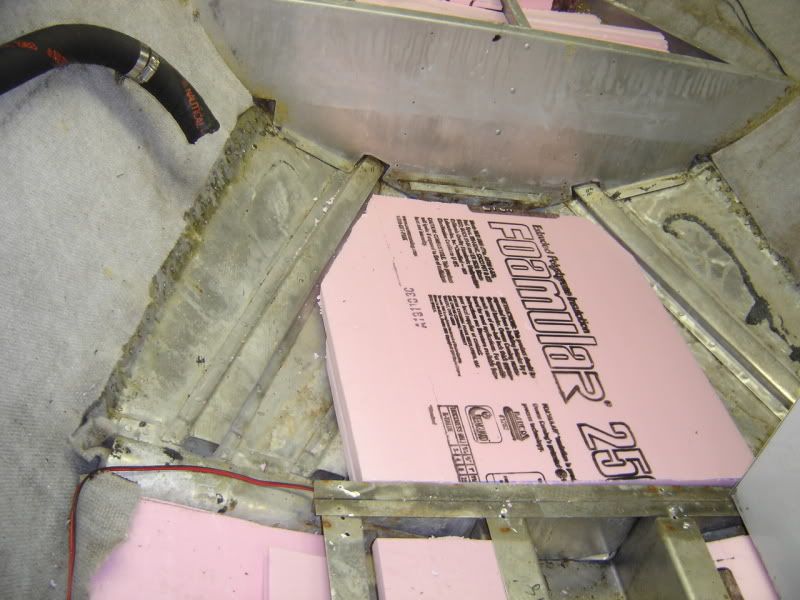

That all sounds good on paper, so what did I fit in my boat?

I put absolutely every bit of foam I could in the back of the boat to try to level float it if things ever went that bad. I had a bellows rip on another boat one time and man the water comes in fast. I can?t think of another thing that would put that much water in the boat except tearing the bottom out of it.

In total I got four 2? boards, one 1.5 inch board, and four ? inch boards, for a total of (4*2.7)+(1*2.0)+(4*1.0) = 16.8 cu ft, which will float (16.8x62.4) = 1048 pounds

With 650 pounds for the drive train, plus 400 pounds for the boat, brings my guess for the total weight to 1050 pounds. Pure luck, but it looks like I?m right on the line.

The USCG goes into a discussion about things that float in the boat, that if tied to the boat will keep it from going to the bottom, like seats, trapped air in fuel tanks, trapped life preservers, and some help from things that also help like the wood (decks etc) in the boat.

An empty 10 gallon tank is 1.3 cu fit, which will float 1.3*62.4 = 83 pounds

Guessing a seat would displace about 10 gallons, having 4 bigish seats probably more, that?s 330 pounds, which puts me comfortably over sinking (assuming my weight estimates are decent).

Now for the money part of it?.

The pink foam at HD cost about $5.18 per cubic foot ($14 for a 2? sheet)

The blue buoyancy billets cost about $11.5 per cubic foot at the local lumber yard ($89 for a 7? x 20? x 8? piece).

Poured in place foam is $13.25 per cubic foot, based on a 8 cu ft kit for $105

I replaced the transom in my boat because of the original poured foam trapping water against it. The poured foam also trapped water in small pockets against the deck, and prevented the water from moving freely in the bilge to the pump. The slow moving water didn't clean the stuff out from between the ribs etc, making it trap even more water, adding to making the decks soft. All strikes against pouring again (at least in my opinion). The money part is obvious.

The moral of the story, based on my boat, get every bit of foam board you can in the boat and you?ll float the boat in a worst case situation, for way less than half the price of poured foam, with none of the poured foam issues.

So I did some math, that I thought I?d share with others, that is pretty practical.

May seem like one of those math quizzes, but it does work?

Fresh water weighs 62.4 pounds per cubic ft, so one cubic foot of foam will float 62.4 pounds. (I?m not going to consider the weight of the foam in these calculations because it would have a minimal impact.)

So, if I want to know how much foam I need to float my 3.0 OMC I/O setup, the first thing I need to know is how much the drive train weighs. I asked here, and a got a couple of different answers, but the average estimate seems to be about 650 pounds.

How many cu ft of foam would I need? 650/62.4 = 10.4 cubic feet.

What do you do with the 10.4 cubic feet?

A 2? thick x 24? wide x 8? (96?) long foam board is 4608 cu in.

Divide cu in by 1728 to get cubic feet.

4608/1728 = 2.7 cubic feet per board.

To get to the needed 10.4 cubic feet, you need 10.4/2.7, or 3.9, which rounds up to four 2? boards

So, 4 two inch boards will float by drive train.

I guessed that the rest of the aluminum boat weighs in at 400 pounds.

To float 400 pounds I need 400/62.4 = 6.4 cubic feet of foam

6.4/2.7 = 2.3, so I need another two and a third 2? boards, for a total of 6.3, to float the whole boat.

Now 2? foam won?t fit everywhere, so here?s the numbers for the other foam boards at HD.

2? thick is 2.7 cu ft per board

1.5 inch thick is 2.0 cu ft per board

1 inch thick is 1.3 cu ft per board

? inch thick is 1.0 cu ft per board.

That all sounds good on paper, so what did I fit in my boat?

I put absolutely every bit of foam I could in the back of the boat to try to level float it if things ever went that bad. I had a bellows rip on another boat one time and man the water comes in fast. I can?t think of another thing that would put that much water in the boat except tearing the bottom out of it.

In total I got four 2? boards, one 1.5 inch board, and four ? inch boards, for a total of (4*2.7)+(1*2.0)+(4*1.0) = 16.8 cu ft, which will float (16.8x62.4) = 1048 pounds

With 650 pounds for the drive train, plus 400 pounds for the boat, brings my guess for the total weight to 1050 pounds. Pure luck, but it looks like I?m right on the line.

The USCG goes into a discussion about things that float in the boat, that if tied to the boat will keep it from going to the bottom, like seats, trapped air in fuel tanks, trapped life preservers, and some help from things that also help like the wood (decks etc) in the boat.

An empty 10 gallon tank is 1.3 cu fit, which will float 1.3*62.4 = 83 pounds

Guessing a seat would displace about 10 gallons, having 4 bigish seats probably more, that?s 330 pounds, which puts me comfortably over sinking (assuming my weight estimates are decent).

Now for the money part of it?.

The pink foam at HD cost about $5.18 per cubic foot ($14 for a 2? sheet)

The blue buoyancy billets cost about $11.5 per cubic foot at the local lumber yard ($89 for a 7? x 20? x 8? piece).

Poured in place foam is $13.25 per cubic foot, based on a 8 cu ft kit for $105

I replaced the transom in my boat because of the original poured foam trapping water against it. The poured foam also trapped water in small pockets against the deck, and prevented the water from moving freely in the bilge to the pump. The slow moving water didn't clean the stuff out from between the ribs etc, making it trap even more water, adding to making the decks soft. All strikes against pouring again (at least in my opinion). The money part is obvious.

The moral of the story, based on my boat, get every bit of foam board you can in the boat and you?ll float the boat in a worst case situation, for way less than half the price of poured foam, with none of the poured foam issues.