stancalame

Petty Officer 2nd Class

- Joined

- May 10, 2014

- Messages

- 113

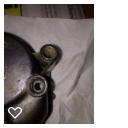

Had a wierd day. Finally got my shifter back together and was double checking timing with boat in water but on boat lift. Water intake was below the surface. I just replaced impeller and seal in early sping and its been running great, rarely getting over 160F. I diconnected the water line that comes in from the transom and feeds the circulating pump and there is no water being delivered to the circulating pump from the impeller on the back of the upper housing. I back flshed and observed water going our the starbord side of the lower gear housing. I placed muffs on the water intake and observed water coing out of the port side wter passages, the side that feeds the impeller. So best I can tell, I do not have any blockages. The only thing I know to do is replaced the seal on the water impeller housing and new gasket. When I took of the impeller housing the oring seal was town in two places but I may have torn it when taking it off. Any ideas or coaching while I chase this problem? Any insight?