Even checked them with my kids microscope. Don't see anything shiny.Thanks. They look quite clean. Nothing metallic on themView attachment 363939

Even checked them with my kids microscope. Don't see anything shiny.Thanks. They look quite clean. Nothing metallic on themView attachment 363939

Hello, Can i ask you one question?Two red flags.

Going from aluminum to stainless, you normally need to drop 1" in pitch. You kept it the same

Going from 3 blades to 4 you normally need to drop 1" in pitch. You kept it the same

To go from a 3 blade aluminum to a 4 blade stainless, you should be at 17p. Not the 19p you bought.

You are lugging your motor. That rattling is the motor detonating and eating itself

30 years ago you'd have been right, not today.Going from aluminum to stainless, you normally need to drop 1" in pitch. You kept it the same

Going from 3 blades to 4 you normally need to drop 1" in pitch. You kept it the same

To go from a 3 blade aluminum to a 4 blade stainless, you should be at 17p. Not the 19p you bought.

Not to mention droplets of metal welded right to them.Ayuh,..... With all the damage to those plugs after only 8 hrs. run time, I'm goin' with massive detonation,.....

The corners of the electrodes are rounded right off,....

So what could be the cause and possible solutions?Not to mention droplets of metal welded right to them.

Ayuh,..... Timin' to advanced, or more likely, a lean condition, when it can't make enough power to get to Wot, at 4800 rpms,.... aka: lugging,...So what could be the cause and possible solutions?

Thanks. I will start with the fuel mixture. The strange thing is this engine can easily get to 4800 RPMs. Runs smoothly. Except for the noise with the 4-blade prop, the engine appears to be performing great.Ayuh,..... Timin' to advanced, or more likely, a lean condition, when it can't make enough power to get to Wot, at 4800 rpms,.... aka: lugging,...

Check that that the timing not only intial but full advance is correctQuick one here before I go into troubleshooting mode this weekend.

About the fuel mixture adjustment. I'm going to tune it as per the manual but isn't that needle only for Idling? I mean, should that affect the engine's performance while revving high RPMs?

I'll check the timing is correct (it should be 6° BTDC as per the manual). If it is, what else can I check? Maybe try higher octane fuel?

Thanks for the details. I plan to rebuild the carb offseason.Check that that the timing not only intial but full advance is correct

As mentioned by others the idle mix screw is only for idle through about 1500 rpm then the main venturi takes over. Things that will lean out main mix is any obstruction in fuel delivery-

Pump

pick up tube clogged

antisiphon valve

clogged fuel filter (normally in bowl in bottom of fuel pump on 3.0)

Fuel tank vent plugged

Also carb could be be in need of teardown, cleaning, and rebuild.

If the main jets or power valve (or piston for power valve) is clogged they will run lean.

Also, can anyone help me confirm the right manual for my engine (L375837)? Is it #26 or #10? When I enter the serial number in https://www.mercruiserparts.com/ it throws this range:Check that that the timing not only intial but full advance is correct

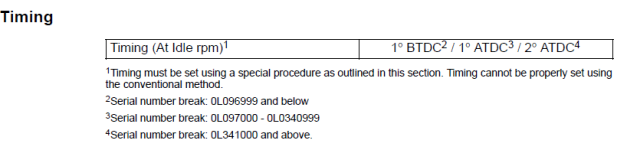

Seems correct for your serial number- your initial timing (set in base mode) should be 1 deg BTDC- not in base mode 12 deg , then total timing 23 BTDC at 2800 rpm. if for some reason module is bad could be pulling in more advance... or could need settingAlso, can anyone help me confirm the right manual for my engine (L375837)? Is it #26 or #10? When I enter the serial number in https://www.mercruiserparts.com/ it throws this range:

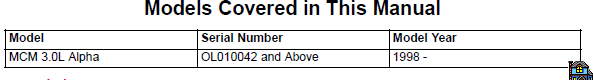

3.0L GM 181 I/L4 1 1998 - 0L010042 THRU 0L096999

And that corresponds to Manual #26.

View attachment 368747

If it's indeed 26, then the initial timing varies. I assume mine is 1 BTCD, correct?

View attachment 368743

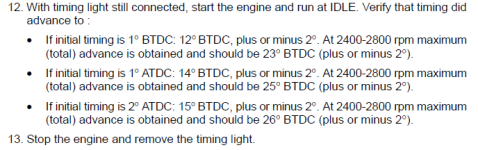

As per manual #26, full advance timing should be automatically set by the distributor after setting the Initial Timing at Idle.

View attachment 368746

Must be gettin really old as this does not make much sense to this old brain...When you add an extra blade with the same pitch, you should be moving more water which puts more strain on an engine. Just for curiosity, I have been looking at getting a spare prop for my boat. Thinking a change in blades, pitch etc might squeek out a little more speed. In all the sites I have been to, they have always recomended dropping 1-2" in pitch when moving to a 4 blade. Now I am more confused than ever, gettin old I guess....30 years ago you'd have been right, not today.

About then Merc released their new range of props, along with a parts bulletin outlining that the old philosophy of dropping an inch of pitch was no longer needed as the new rengineering and design of props matched inch for inch across 3 and 4 blade and regardless of materials... Other manufacturers have also followed suit.

Chris...

And this would explain why the 4 blade prop exposed the timing issue of my engine.When you add an extra blade with the same pitch, you should be moving more water which puts more strain on an engine.

I know this is an old thread. Let me know if a new one is required.Also, can anyone help me confirm the right manual for my engine (L375837)? Is it #26 or #10? When I enter the serial number in https://www.mercruiserparts.com/ it throws this range:

3.0L GM 181 I/L4 1 1998 - 0L010042 THRU 0L096999

And that corresponds to Manual #26.

View attachment 368747

If it's indeed 26, then the initial timing varies. I assume mine is 1 BTCD, correct?

View attachment 368743

As per manual #26, full advance timing should be automatically set by the distributor after setting the Initial Timing at Idle.

View attachment 368746