sphelps

Supreme Mariner

- Joined

- Nov 16, 2011

- Messages

- 11,508

Guys , quick maybe dumb question.

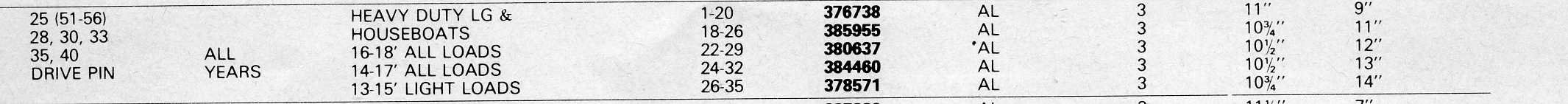

So I repowered my 16.5 Wagemaker wooden boat with a nice 1958 35 hp Big Twin Evinrude . It came with 3 props .

3 blade 10-3/8 x 11-1/2 aluminum

3 blade 10-3/8 x 14. Aluminum

2 blade not sure what pitch but has numbers BSP19320. And AJC46J on it . This prop was being used on a 14’ Aristocraft little speedboat .

I’m gunna lake test this weekend on wondering which prop makes the most since to start with . I do not have a tach on it so I know it’s gunna be tough to really know for sure on the right prop . Hopefully one of the 3 will work well . I’ll have access to a hand held tach in my next AOMCI trip to the Suwannee in a couple months .

Just wanting opinions on which to try this weekend for a test run ..

So I repowered my 16.5 Wagemaker wooden boat with a nice 1958 35 hp Big Twin Evinrude . It came with 3 props .

3 blade 10-3/8 x 11-1/2 aluminum

3 blade 10-3/8 x 14. Aluminum

2 blade not sure what pitch but has numbers BSP19320. And AJC46J on it . This prop was being used on a 14’ Aristocraft little speedboat .

I’m gunna lake test this weekend on wondering which prop makes the most since to start with . I do not have a tach on it so I know it’s gunna be tough to really know for sure on the right prop . Hopefully one of the 3 will work well . I’ll have access to a hand held tach in my next AOMCI trip to the Suwannee in a couple months .

Just wanting opinions on which to try this weekend for a test run ..