ok, after trying in vain to come up with other ideas on how to fix my 19' water-loo, I've decided to take the advice of all who have responded to my posts and do this right.

I have spent hours going over all these posts and still am a bit confused as to what I will need to get my project done. So much info I am feeling over whelmed. It has taken a few weeks to get the jargon (stringers?!?) down as well as trying to decipher things like MEKP, csm, 5200 and all the other things that make a guy go, huh?!? Not to mention when I first read about 16lb kits of foam I nearly gave up on the whole thing!

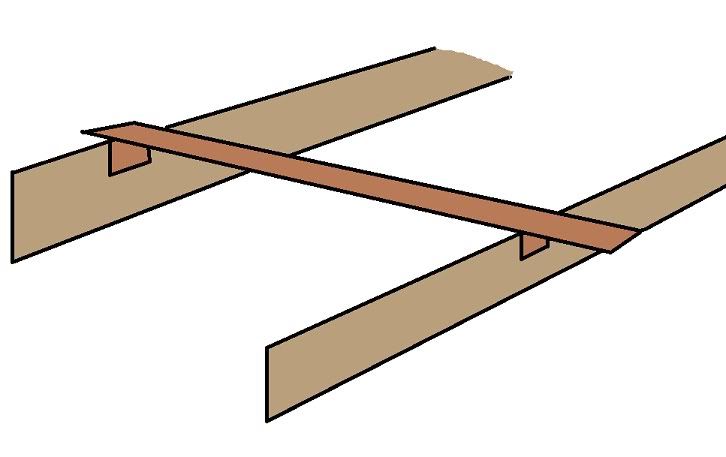

With that said, I'm replacing the under deck, hull frame, stringers, etc...(transom is good for some reason, but i'm not complaining! )

)

I've got the wood bought, and I went to this website http://www.uscomposites.com/foam.html (thanks jigngrub) and found the 2lb foam. I figure two 16lb kits should get me done. Other than that, I am in the dark and over whelmed with what I will need to get my project done. I've got gelcoat cracks that need fixed, a nice 6" long grinder hole in the hull to fix, gonna be taking off the rub rail and re-doing the cap-hull connection. I would like a parts list of glues, resins, FG, Safety equipment, PB fixin's, grinding material and anything else you can possibly think of that I can order to get this done!

I call upon the FG boat guru's to once again, help a wayward, FG eatin', poisonous fume breathin', skin scratchin', coca-cola drinkin'-- just wanted to buy a boat to have fun, brother out.

And I wish to express my heart felt thanks to any and all who have taken there time to answer my posts and direct me towards the path I am currently on. Your help has been so appreciated. I remember the sinking feeling I had when I pulled that drill bit from the back of my transom and saw what was supposed to be dry wood but looked more like wet peat moss. Through this forum I now have hope and I have the likes of oops, jigngrub, Yacht Dr., ondarvr and so many others for bringing me hope and showing that it can be done. Yes, there is a light at the end of the tunnel and I'm pumped up! Let's git er done!

I have spent hours going over all these posts and still am a bit confused as to what I will need to get my project done. So much info I am feeling over whelmed. It has taken a few weeks to get the jargon (stringers?!?) down as well as trying to decipher things like MEKP, csm, 5200 and all the other things that make a guy go, huh?!? Not to mention when I first read about 16lb kits of foam I nearly gave up on the whole thing!

With that said, I'm replacing the under deck, hull frame, stringers, etc...(transom is good for some reason, but i'm not complaining!

I've got the wood bought, and I went to this website http://www.uscomposites.com/foam.html (thanks jigngrub) and found the 2lb foam. I figure two 16lb kits should get me done. Other than that, I am in the dark and over whelmed with what I will need to get my project done. I've got gelcoat cracks that need fixed, a nice 6" long grinder hole in the hull to fix, gonna be taking off the rub rail and re-doing the cap-hull connection. I would like a parts list of glues, resins, FG, Safety equipment, PB fixin's, grinding material and anything else you can possibly think of that I can order to get this done!

I call upon the FG boat guru's to once again, help a wayward, FG eatin', poisonous fume breathin', skin scratchin', coca-cola drinkin'-- just wanted to buy a boat to have fun, brother out.

And I wish to express my heart felt thanks to any and all who have taken there time to answer my posts and direct me towards the path I am currently on. Your help has been so appreciated. I remember the sinking feeling I had when I pulled that drill bit from the back of my transom and saw what was supposed to be dry wood but looked more like wet peat moss. Through this forum I now have hope and I have the likes of oops, jigngrub, Yacht Dr., ondarvr and so many others for bringing me hope and showing that it can be done. Yes, there is a light at the end of the tunnel and I'm pumped up! Let's git er done!