gm280

Supreme Mariner

- Joined

- Jun 26, 2011

- Messages

- 14,605

I have been seeing and reading a new way to clean fired empty brass for reloading. And I looked at lots of tumblers that a lot of folks built. So only having a mere small tumbler from years ago that I used to clean brass cases, I decided to make a new larger machine. Well I did and here is that new tumbler. It still needs to be painted for the final finish, and that comes shortly as well.

Seems the new method to clean empty brass is to use stainless steel pins. I know, that doesn't sound right, but you will be a believer shortly. These pins are about .047" in diameter and about .250" long. They are sold by the weight. And you put them in the tumbler with water and some detergent. But not just any detergent. They recommend Lemon Shine (actual brand name). So here are the before and after pictures of the first batch in the new tumbler I built.

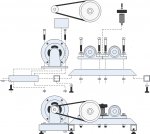

This is the tumbler. It is built out of 1.25" square tubing with 3/4" pillow bearing and 3/4" black iron pipe and a 1/2 HP motor. It is sold as a rock and can tumbler anything you can throw at it.

A few pictures of the tumbler. Now lets see how well it works.

These are 223 cases sized, deprimed and even the military primer pockets swagged if needed. You can see they are pretty cruddy and stained. The first batch was 500 cases. Not even a half filled tumbler, but I wanted to see how well this thing worked. This load weighted in a just a little over 25lbs.

Same case after only an hour and 40 minutes. Usually you tumble for 2 to 3 hours, but I couldn't wait.

They look like new inside and out. No dirt, stains or any discoloration now. Even the primer pockets are cleaned as well. A task I hated to do by hand. So now a new primer, some powder and a bullet and we are ready to rock and roll. I had to show this for other reloaded that I know a lot of iboats do as well.

I will never reload dirty ammo case ever again. These will rivil new ammo without any problem.

Seems the new method to clean empty brass is to use stainless steel pins. I know, that doesn't sound right, but you will be a believer shortly. These pins are about .047" in diameter and about .250" long. They are sold by the weight. And you put them in the tumbler with water and some detergent. But not just any detergent. They recommend Lemon Shine (actual brand name). So here are the before and after pictures of the first batch in the new tumbler I built.

This is the tumbler. It is built out of 1.25" square tubing with 3/4" pillow bearing and 3/4" black iron pipe and a 1/2 HP motor. It is sold as a rock and can tumbler anything you can throw at it.

A few pictures of the tumbler. Now lets see how well it works.

These are 223 cases sized, deprimed and even the military primer pockets swagged if needed. You can see they are pretty cruddy and stained. The first batch was 500 cases. Not even a half filled tumbler, but I wanted to see how well this thing worked. This load weighted in a just a little over 25lbs.

Same case after only an hour and 40 minutes. Usually you tumble for 2 to 3 hours, but I couldn't wait.

They look like new inside and out. No dirt, stains or any discoloration now. Even the primer pockets are cleaned as well. A task I hated to do by hand. So now a new primer, some powder and a bullet and we are ready to rock and roll. I had to show this for other reloaded that I know a lot of iboats do as well.

I will never reload dirty ammo case ever again. These will rivil new ammo without any problem.