Hi all

My first time posting on this forum.

I picked up a BLAF / BF45A which I am in the process of swapping power heads. The original motor is getting water into the combustion chamber (previous owner had corrosion on head welded / resurfaced / new head gasket, to no avail), and I just happened to have a brand new power head in my shed for the same.

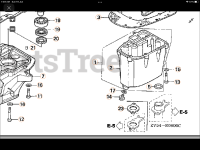

I have the factory shop manual, and I am at the point of removing the oil pan. I have removed the (11) 6x25mm bolts around the outside / underside periphery of the pan but I have left the exhaust tube and water tube installed, but it doesn’t seem to want to break free? I’ve given it a few good taps with a rubber mallet, but I am hesitant to get too brutal with it for fear of cracking the pan. Is there a step I’m missing here? Or am I just being too gentle with the mallet?

Thanks in advance.

My first time posting on this forum.

I picked up a BLAF / BF45A which I am in the process of swapping power heads. The original motor is getting water into the combustion chamber (previous owner had corrosion on head welded / resurfaced / new head gasket, to no avail), and I just happened to have a brand new power head in my shed for the same.

I have the factory shop manual, and I am at the point of removing the oil pan. I have removed the (11) 6x25mm bolts around the outside / underside periphery of the pan but I have left the exhaust tube and water tube installed, but it doesn’t seem to want to break free? I’ve given it a few good taps with a rubber mallet, but I am hesitant to get too brutal with it for fear of cracking the pan. Is there a step I’m missing here? Or am I just being too gentle with the mallet?

Thanks in advance.