Jconnell43

Petty Officer 3rd Class

- Joined

- Sep 4, 2005

- Messages

- 85

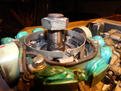

Are these terminal gouges in my crankshaft 1971 Johnson 50.

I pulled the flywheel on good advice from a forum member to find my woodruff key had disintegrated and I presume had left crank gouges.

Are these repairable with let's say filling with JB Weld or some other method.

These are all gouges that are recessed, no metal above the crank surface.

Boat doesn't see a lot of use, especially at WOT.

I pulled the flywheel on good advice from a forum member to find my woodruff key had disintegrated and I presume had left crank gouges.

Are these repairable with let's say filling with JB Weld or some other method.

These are all gouges that are recessed, no metal above the crank surface.

Boat doesn't see a lot of use, especially at WOT.