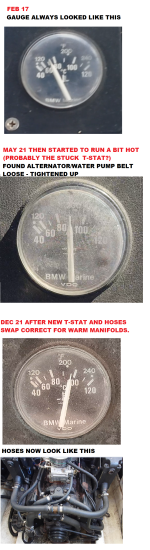

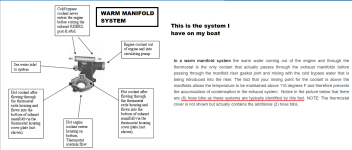

Hi all - my 1st post. Have a 1986 alpha1 5.7L which has recently had a new impeller (mechanic fittted) and a new thermostat (me fitted). During the thermostat fitting I discovered that the upper cooling hoses were wrongly connected so rectified IE t-stat cover outlets to bottom of manifolds, and foward T style outlet hoses to the risers (have had dry joint manifolds fitted x mechanic recently as well). Anyway as I drained a lot of the sitting water out of my system during the hose work I guess the water in the block and manifolds was pretty dry. Anyway upon starting up on the muffs (garden hose full bore has been OK in the past for flow) the engine temp gauge quickly got up to around 200deg F so quickly shut down - then heard a loud rapid ticking sound and boiling sounds, manifolds and risers too hot to rest hand on, but both seemed to be about the same temp. My next idea is to try with the leg in a large drum of water. Could my problem be low flow from muffs not filling out engine internal passages so some sort of air lock? The hoses to the manifolds and risers seem to be hot to touch as well so probably flowing out of t-stat housing. I am also thinking of getting some clear hoses to fit in-line to double check for flow? Possibly also connect hose directly to circulation pump on front of engine and check the flow out of the leg feed hose to see if impeller doing OK. Very low on funds so have to try to self solve to avoid stiff mechanic bills!

- Shop

-

Main Menu Find The Right Fit

-

-

Slide Anchor Box Anchors Shop Now

-

Back Fishing

-

View All

- Fishing Rods

- Fishing Reels

- Fishing Rod & Reel Combos

- Fishing Tools & Tackle Boxes

- Fishing Line

- Fly Fishing

- Fishing Bait & Fishing Lures

- Fishing Rod Holders & Storage Racks

- Fish Finders, Sounders & Sonar

- Trolling Motors

- Fishing Nets

- Fishing Downriggers & Acessories

- Fishing Outriggers & Acessories

- Fishing Kayaks

- Fish Cleaning Tables

-

-

Minn Kota Riptide Terrova 80 Trolling Motor w/i-Pilot & Bluetooth Shop Trolling Motors

-

SportsStuff Great Big Marble Shop Tubes

-

Big Jon Honda 5hp Outboard Shop Outboards

-

Lexington High Back Reclining Helm Seat Shop Helm Seats

-

Kuuma Stow n Go BBQ Shop Now

-

Slide Anchor Box Anchors Shop Now

-

Back Electrical

-

View All

- Boat Wiring & Cable

- Marine Batteries & Accessories

- Marine DC Power Plugs & Sockets

- Marine Electrical Meters

- Boat Lights

- Marine Electrical Panels & Circuit Breakers

- Power Packs & Jump Starters

- Marine Solar Power Accessories

- Marine Electrical Terminals

- Marine Fuse Blocks & Terminal Blocks

- Marine Switches

- Shore Power & AC Distribution

-

-

ProMariner ProNautic Battery Charger Shop Marine Battery Chargers

-

Lowrance Hook2-4 GPS Bullet Skimmer Shop GPS Chartplotter and Fish Finder Combo

-

Boston Whaler, 1972-1993, Boat Gel Coat - Spectrum Color Find your boats Gel Coat Match

-

Rule 1500 GPH Automatic Bilge Pump Shop Bilge Pumps

-

Back Trailering

-

SeaSense Trailer Winch Shop Trailer Winches

-

Seadog Stainless Steel Cup Holder Shop Drink Holders

-

Slide Anchor Box Anchors Shop Now

-

- Boats for Sale

- Community

-