BamaBowrider 208

Seaman

- Joined

- Jan 4, 2021

- Messages

- 74

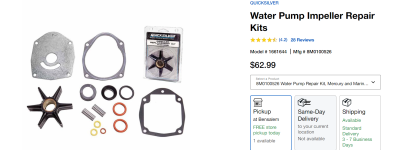

I have a couple of questions for the experts here. This is the first time I have replaced the impeller on this outdrive. While removing the lower unit, I found that the front mounting bolt had red loctite on it, not sure why. After removing the lower unit, I found that there was no water seal around the shaft. I have no idea who worked on this last. Anyway, I assume that the thing around the outlet tube was once the guide? What would cause this to shrink up like that, excessive exhaust gas temps?

I watched Chris' replacement/assembly videos in the sticky section, but still have a few more questions........

Should all of the mounting bolt threads be greased only?

Should any sealant be used between the gaskets and plate of the water pump housing?

Do I need to replace the outlet tube guide or can it be reassembled without it?

Thanks in advance for answers and advice.

I watched Chris' replacement/assembly videos in the sticky section, but still have a few more questions........

Should all of the mounting bolt threads be greased only?

Should any sealant be used between the gaskets and plate of the water pump housing?

Do I need to replace the outlet tube guide or can it be reassembled without it?

Thanks in advance for answers and advice.