Hello,

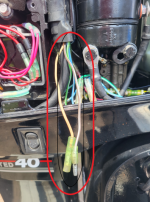

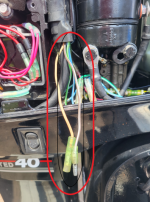

I have a '97 Mercury 40hp (s/n 0D128799) and the warning module has decided to act up. I'd like to switch to pre-mix (another topic) and add a temperature sender/gauge. There is a brass plug on the head where I can add the sender but am wondering about the wiring. The remote wiring harness end on the engine side has two wires that are connected together (brown-white + tan). At the throttle side, I have a loose tan wire. When testing continuity, it seems the tan wire from motor end is the same one that is on the throttle end.

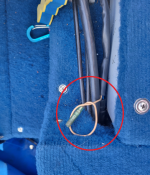

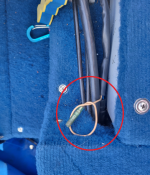

Throttle end (loose wire)

Thanks,

Kevin

I have a '97 Mercury 40hp (s/n 0D128799) and the warning module has decided to act up. I'd like to switch to pre-mix (another topic) and add a temperature sender/gauge. There is a brass plug on the head where I can add the sender but am wondering about the wiring. The remote wiring harness end on the engine side has two wires that are connected together (brown-white + tan). At the throttle side, I have a loose tan wire. When testing continuity, it seems the tan wire from motor end is the same one that is on the throttle end.

- Does anyone know if this is the wire to use for the temperature sender (the jet version of this engine has one)

- What is the purpose of the brown-white wire on the motor end and why was it connected to tan?

Throttle end (loose wire)

Thanks,

Kevin