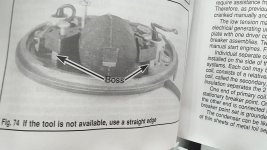

Little alignment bosses that you use a straight edge on.

Thanks, when I had the flywheel off earlier thats what the charge and sensor coil line up with on my motor as well.

So here are the results of the testing with the DVA - charge coil voltage is around 275 volts at cranking. Down a bit from the 300+ taken with the Fluke on peak mode.

Sensor coil voltage reads about 12-15 volts with the DVA, down from the 20+ with the Fluke. So it seems that while the 88V on peak mode will get you ballpark readings if a component is good or bad, the DVA adapter is still great to have for more accurate readings.

After installing the new CDI sensor coil, it was rubbing against the flywheel even pushed back as far as I could. I shaved some off the plastic mounting holes to get it back further, and the magnets were still just grazing the plastic on the outer edge of the coil face. It literally looks like they pour the plastic over the coil, then just shove it on a belt sander until it's ground down a bit and call it good. Not impressed with the quality of that one.

I rubbed away at it with my knife for a bit and got it to where I can just barely hear a faint tick from plastic getting rubbed as it scraped by. Good enough for a test. After that, threw the flywheel back on and the recoil starter and got around 5 volts cranking with no plugs in. Still higher than spec, but much closer.

Since I don't have the tools to push the pin out of the rubber connectors, I cut the old coil wires near the plug, stripped the wires left on the plug, and wrapped them around the new pins for the time being. I guess I need to get the tools to do it all the right way, as I need to remove ALL the wires from the plug to put heat shrink around the new sensor and old charge coil wires to protect them from abrasion. Until I spend more money on tools for this motor though, I will just cut the pins off the new coil and solder the wires together at the rubber connector.

Immediately after starting I noticed the engine returns to idle better. You can give it a rev, let it idle down and it just sits there happily no problem. Huge improvement. It still doesn't like going down as low as 700ish, but then again that may be the inductive pickup I have for the DMM reading it wrong.

I still get some 4-stroking/missing at mid-rpms. I hooked two little test lights up between the spark plugs and the wires and watched them. Sometimes #2 would occasionally drop out a bit. Not for any amount of time, but definitely a miss here or there.

Finally found my spark tester that you can set a gap on. Coil for #1 is sparking like a champ, it will jump almost 3/4 of an inch no problem.

#2 however will start missing occasionally at not even 1/4 of an inch.

Swapped the plug wires to the same result.

Tried to do the running voltage test by jamming a wire up in the primary connector at the ignition coil from the power pack, but only saw around 4-5 volts for #1. This must not work well, I think I need the extender.

So, we're dropping down to idle much better now, but still not idling low enough, and still some 4-stroking in mid-higher range RPMs.

Ordered a CDI ignition coil after seeing the weak spark on #2 compared to #1. Should be here Sunday. Hope it's a better quality coil than their sensor coil is, lol. I can get a Sierra coil but not until later next week. I'm determined to see this thing run right this weekend.

Cautiously optimistic I'm finally getting somewhere. Even the little win with the new sensor coil letting things come down to idle smoother has me in a better mood.