Matthewg94

Cadet

- Joined

- Feb 26, 2021

- Messages

- 11

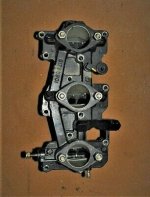

So I just rebuilt my 1989 force 85hp 856x9E and it won't start. I used a newer 90hp block with the rebuild. Wiseco pistons to match the bore. I'm getting 140 psi on all 3 cylinders. I have spark on all 3 cylinders. I verified that fuel is getting to all the carburetors. When I cover each carb with my hand it would sputter a bit and gas would pour out of the carb. The top carb has noticable suction. The bottom 2, I'd have to double check but they didn't seem to have as much vacuum in them. I have the mixture screws set at 1.5 turns out. When I prime the carbs with a bottle of premix it sounds like it's trying to start for a moment but never actually runs on it's own for more than half a second. I checked the reeds and none of them are stuck open at all. My only concern is that there may be a vacuum leak somewhere, but where? One thing I noticed about the 90hp block is that there are 3 small 1/8 vacuum fittings on each side of the motor 6 total. I figured I would eliminate those since they are part of a recirculation system that I didn't have on my 89 so I ran vacuum lines from each side to each other. Other than that I have one unaccounted for fitting, right on the bottom of the reed plate. So are there any vacuum leaks I should be looking for? Or could it be a possible wiring problem like mismatched wires causing the wrong firing sequence?