I have a 8.1 GXI-J Volvo Penta and took the boat out on Saturday for a ride where after about a minute on plane the boat died on me, alarms went off, and would not turn back on. After waiting a few minutes, the boat did start back up and I was able to get it back home to my dock. The boat starts once each morning (Sunday and today) but after that, it will not start again. A few things I observed below:

- after the boat died, I came back at the lowest speed possible, but as I attempted to accelerate to see what would happen, the ECT/coolant temps would drop from the 150/160 range down to 100, as soon as I let off the throttle back to the lowest speed, the temps crept back up (I tried this a few times, consistent each time)

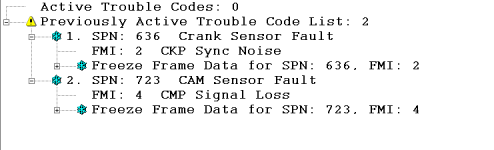

- when the boat died, 2 alarms went off - when I plugged in my Diacom once I got home, there was a "Crank Sensor Fault" code and "Cam Sensor Fault" code

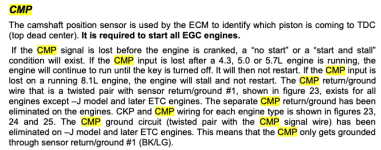

- when trying to start the boat after the first time, the "engine speed RPMs" within DIACOM never go above 200 rpm - I read somewhere that it needs to be in the 200-300 range for the engine to know to start - is this true? Would that be a bad crank sensor signal?

- the batteries are fully charged, 3/4 tank of gas, starter is actively cranking, fuel pump is priming, it just won't turn over

I have 2 Diacom logs below. The first one, is after the boat ran for 10 minutes, then I turned it off and immediately tried to re-start and it wouldn't. Towards the end of the 10 minutes you will see the ECT/coolant temp fluctuations I mentioned above where they would drop and rise a few times (the boat sat in idle the entire time). You will also see the 2 Codes that were flagged. The second log below is just me attempting to start the boat a few times. Video also attached of attempting to start

drive.google.com

drive.google.com

drive.google.com

drive.google.com

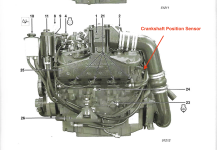

Doing some digging on this forum and online, I saw some tips that if the Crankshaft position sensor is bad/off then it won't allow the engine to start. Does anyone have insights into this? If anything else stands out from the logs please let me know

@muc @alldodge @tpenfield as you were all extremely helpful with my last issue

- after the boat died, I came back at the lowest speed possible, but as I attempted to accelerate to see what would happen, the ECT/coolant temps would drop from the 150/160 range down to 100, as soon as I let off the throttle back to the lowest speed, the temps crept back up (I tried this a few times, consistent each time)

- when the boat died, 2 alarms went off - when I plugged in my Diacom once I got home, there was a "Crank Sensor Fault" code and "Cam Sensor Fault" code

- when trying to start the boat after the first time, the "engine speed RPMs" within DIACOM never go above 200 rpm - I read somewhere that it needs to be in the 200-300 range for the engine to know to start - is this true? Would that be a bad crank sensor signal?

- the batteries are fully charged, 3/4 tank of gas, starter is actively cranking, fuel pump is priming, it just won't turn over

I have 2 Diacom logs below. The first one, is after the boat ran for 10 minutes, then I turned it off and immediately tried to re-start and it wouldn't. Towards the end of the 10 minutes you will see the ECT/coolant temp fluctuations I mentioned above where they would drop and rise a few times (the boat sat in idle the entire time). You will also see the 2 Codes that were flagged. The second log below is just me attempting to start the boat a few times. Video also attached of attempting to start

Volvo EGC CAN ETC 08 28 2023 09 01 33.rec

drive.google.com

drive.google.com

Volvo EGC CAN ETC 08 28 2023 09 14 40.rec

drive.google.com

drive.google.com

Doing some digging on this forum and online, I saw some tips that if the Crankshaft position sensor is bad/off then it won't allow the engine to start. Does anyone have insights into this? If anything else stands out from the logs please let me know

@muc @alldodge @tpenfield as you were all extremely helpful with my last issue