On the first real trip this year after finally getting my mechanic to pull the engine to correct a vibration problem from a flywheel that was installed in the wrong positions my 7.4 B1 Merc was running very well, but when running at speed it quickly filled the bilge with smoke, and upon inspection it had melted the lower rubber exhaust boot.

This is a recently rebuilt "rebuild" that had to be redone due to either the rebuilder or original marina not getting things exactly right and nearly everything except the transom assembly is now new or rebuilt. So yes it has a new impeller, the correct intake thick wall hose, and the circulating pump though approx 3 yrs old now has seen less than 5 hours run time.

It seems my engine is not getting enough water in through transom, and though it runs cool up to around 1500rpm (145f) it gets hot on the gauge quick @ 3000 (approx 170-180) and when I ran it good @ 4000 it shot up to 200f but even with the toasted boot the engine itself did not overheat (thankfully). It does cool down quickly once it is run slow

I did change the risers as they were starting to close up a bit, were cleaned out once before in 09, and were over ten years old etc as a precautionary measure, but I guess you need to get in enough water before you need to be worried about getting it out

I am thinking it is not enough water based on what I had seen coming through this hose in the past when having to change out the impeller as it is much less than before. It is not a trickle, but just a slow steady flow etc.

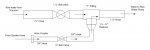

By recommendation of my current mechanic I have already ordered the small hose that goes from the transom to the gimbal and the grommet or flange that holds it in, but I have also been told that these do not normally go bad, and that it is very likely that there may be some growth or obstruction inside the drive itself.

Since it is looking like I will have to be doing this myself due to my mech being busy I wanted to reach out to you guys to get your opinions on what to expect etc. I hear the hose is a real pain if there is much corrosion (this is a 89 so it would not surprise me) and that more than one has been converted to a thru hull intake.

I have also never split the cases on a Bravo before and wanted to learn what to expect, and if there are any seals or other parts needed to re assemble it?

I have a few days as I am waiting on borrowing a trailer to haul it, but since I am borrowing it I want to be sure I have as many parts as I can before removing the drive since I can not keep it on the trailer too long either.

One odd thing was that it did seem to get enough water not to burn the starboard boot, and only the port one. Any ideas on this?

Thanks in advance!!