If you have adjusted the ignition points "exactly" as I explained in a previous post for the point timing to be correct, and.........

If you actually manually cleaned the high speed jets that are located horizontally in the bottom center of the float chamber, way behind the drain screw so that fuel will reach all the other fuel passages as required, and........

If the spark plugs are the proper type and gaped to .030 and the fuel mixture is 50/1..... the engine should start and run in some fashion, perhaps not perfectly but running, unless........

The starting procedure is causing a voltage drop to the Pulse-Pack, Amplifier, Pack, whatever one wants to call it. I prefer the term Pulse-Pack myself as the type of ignition is "Battery Capacitance Discharge" which differs from what we've been used to since 1973, "Magneto Capacitance Discharge" that incorporates Powerpacks.

The main difference between the two is that the magneto capacitance setup develops it own ignition required voltage, whereas the battery capacitance setup requires battery voltage.... and the battery supplied "MUST" be a top notch battery in excellent condition, fully charged, and capable of supplying at least 75 cranking amperes of which most batteries nowadays exceed.

Now, even with a battery as mention above, my point here is that a aging starter system can pull the required voltage away from the Pulse-Pack/Amplifier which results in a non starting engine. The cure for that problem is...........

********************

(Voltage Drop To Battery Capacitance Discharge)

( Pulsepack When Electric Starter Is Engaged)

(J. Reeves)

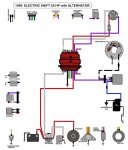

On the older Battery Capacitance Discharge ignition systems (1968-1972), the electric starter reaches a point, even with a top notch battery, whereas the starter will draw excess voltage/current/whatever which results in a voltage drop to the pulsepack. The cure is to purchase a diode which is capable of handling 12 volts and installing it between the starter terminal of the starter solenoid (NOT the battery cable terminal) and the wiring terminal that supplies voltage to the pulsepack.

The diode must be installed so that the current flows from the starter terminal of the solenoid to the pulsepack... NOT vice versa. When that diode is installed in this manner, when the key is turned to the start position, the voltage that is applied to the starter is also applied directly to the pulsepack via the diode effectively eliminating the voltage drop and energizing the pulsepack with the required voltage needed for its proper operation.

********************

Ck eBay Ignition Diode 383538