aarons 470

Petty Officer 1st Class

- Joined

- Aug 29, 2012

- Messages

- 351

Just a progress picture. Wish I could upload better quality pics. Ot won't let me.

Cool thanks. Can I ground stuff to the flywheel cover? Bolt goes Into block.

Or does it have to be directly in the block?

Manual shows a ground stud going through flywheel house with a nut in the center. All I have are bolts. Do I need to pick up that stud?

Do you guys know where I can find a detail for the trim sender? the electrical main drawing we have been using just shows 2 connection points. I have 3, plus the ground. Not sure where my trim sender wire should hook to.

Green goes from sender to lift motor

Green and white goes from sender to small harness below sender.

Larger red wire goes from sender to another actuator? Not sure what it's called.

Is the sender the solenoid looking thing in front of picture? There's is another one that looks different to the left, it's a brown plastic.

The green wires and red wire come of the one in front with silver top.

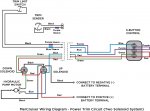

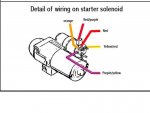

Ok another important one. So the yellow red that comes of right side of slave that's attached to block and goes to starter slave.

Does that wire go to the S or the R on the starter. slave?

And what gauge do you recomend on this?

Going through manual again. So on the flywheel cover stud, I was looking at wrong picture. It's a regular stud there's no nut built in. So a bolt should work fine? I cleaned off All paint at mating surface.

Can this be a major ground, or more for smaller

Grounds?

Where are the 1 or 2 main ground spots on the block for the batteries? Or is flywheel cover

Ok, the wire loom would be against the cover

Though, not actually against engine block. But the ground would flow through the bolts to the block. Is this ok?

On the negative cables for the dual battery switch-

Directions say to run A negative cable from battery to battery.

I ran a negative from each battery to the same place on the block. is this sufficient or do I need to run another one that just goes from battery to battery?