- Joined

- Mar 8, 2009

- Messages

- 43,712

No

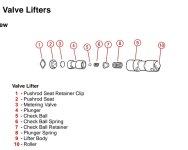

To obtain zero lash hold the push rod with your fingers and feel for up/down slop. Loosen the nut until you feel some up/down movement, turning movement is not used. Once all up/down is gone, this is zero lash. Now turn the nut down one full turn, your done with that lifter

I use a grease pencil and mark nut once done. I also adjust any others that are next to another valve being opened. If valve is being opened then the other of same cylinder is closed

To obtain zero lash hold the push rod with your fingers and feel for up/down slop. Loosen the nut until you feel some up/down movement, turning movement is not used. Once all up/down is gone, this is zero lash. Now turn the nut down one full turn, your done with that lifter

I use a grease pencil and mark nut once done. I also adjust any others that are next to another valve being opened. If valve is being opened then the other of same cylinder is closed