CLi87

Petty Officer 1st Class

- Joined

- Sep 21, 2018

- Messages

- 204

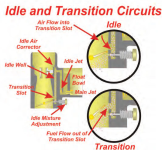

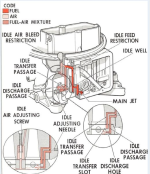

Hey all, I'm working on my 2008 Starcraft with a Volvo Penta 5.0GL with the 2 barrel holley carb. When I got it it had some issues running, when I looked down the carbs I saw one side was dripping fuel fine while the other was only letting out a few drops, so I figured a carb rebuild was in order. I took the carb completely apart and ran it in my ultrasonic cleaner for 30 minutes, then used compressed air @ 175psi to blow out all the passages. After I put it all back together I put it back on the engine and it ran better but the one side still wasn't providing as much fuel as the other side and then after giving it a rev up to 3000 rpms, suddenly the slow side completely stopped dripping fuel. I took the carbs off the engine again and checked for blockages and blew more compressed air through all the passages but didn't see anything come out. I put the carb back on, once again, it would start up and idle fine but I saw one side drip slightly more fuel than the other, and then once again once I gave it a rev up to 3000 rpms and dropped it back down to idle, the one side of the carb stopped dripping fuel. Any idea what would cause this? I was thinking the AF adjustment might be off but on this carb hole on each side of the carb where the AF screws should be is blocked off, so I'm guessing there's no adjustment? Also I know it's not a fuel supply issue as I checked to make sure the fuel pump was pumping plenty of fuel and also when I took the carb off and turned it upside down a lot of fuel came out, so the bowl must be full.