- Joined

- Aug 8, 2020

- Messages

- 11

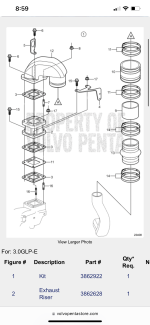

I have 2006 Volvo penta 3.0 GLP-E in a glastron gt185 boat. I replaced the manifold last year because person I bought it from tried to jB weld the underside of it. There was water in the rear or the manifold by cylinder 4. Just chalked it up to was internally cracked as well and replaced it. Inspected the riser and it looked to be ok from what I found see. So I put the old riser back on.

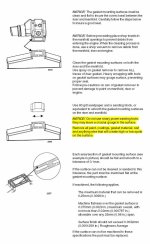

Here is the issue. I have found the water again this year and the engine will misfire. Some key details here as follows: when I start it and let it idle it runs awesome. If I snap the throttle and bring back to idle really quickly it will start to misfire on cylinder 4 . I give it some throttle again and let it burn out the water out approximately 2800 rpms and bring the throttle back slowly to idle it will not misfire. I winterized the boat last year and drained everything. I pulled off the riser last night to inspect and will attach a picture. I have checked compression on all cylinders and all have a reading of 152 psi or more. Where is this water coming from? Do I have another cracked manifold? Or is my head or riser cracked?

Here is the issue. I have found the water again this year and the engine will misfire. Some key details here as follows: when I start it and let it idle it runs awesome. If I snap the throttle and bring back to idle really quickly it will start to misfire on cylinder 4 . I give it some throttle again and let it burn out the water out approximately 2800 rpms and bring the throttle back slowly to idle it will not misfire. I winterized the boat last year and drained everything. I pulled off the riser last night to inspect and will attach a picture. I have checked compression on all cylinders and all have a reading of 152 psi or more. Where is this water coming from? Do I have another cracked manifold? Or is my head or riser cracked?