drobertsobx

Seaman

- Joined

- Nov 1, 2008

- Messages

- 74

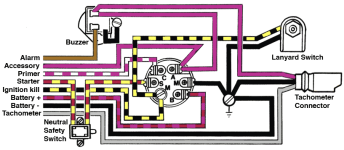

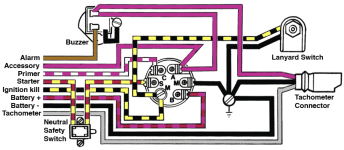

Hi, Just installed a new kill switch and ignition switch and cam roller (was missing when I bought it).

So today was the first start. It would not start where the prev owner had the throttle set.

In fact to get it to run I had to run the screw within 1/2 of the threads (Separate issue I am assuming).

Entire pump was replaced last week.

Using muffs, water streaming from the tell tale it has a weird brass fitting that has a larger hole than anything I have run with that has the plastic fittings, so it wasn't what I would call a strong stream but it was steady... and did get hot water at last check, not sure if it is supposed to or not.

Finally got 1000 RPMS and was using a thermal to monitor temps...

I was leery the thermostats might be salt crusted as it was left in the water by the prev owner.

Good thing I did... within about 1 minute the temp was at 165F (I was assuming it would run in the 140's) both heads then quickly went to 210F, (I heard the alarm at the same instant) and I quickly shut her down by disconnecting the kill switch connector at the power pack.

I monitored the heads after shut down and the maxed out at 217F

I pulled the thermostat head (No small task 1/64th turn at a time with a wrench on the 2 side ones lol), the thermostat gaskets were no where to be seen (Only anomaly in the unit) but it doesn't look close to as corroded as I assumed they would be. (pic)

Grommets were not swollen bypasses seemed to move freely. In the pic the only thing I cleaned was the black plastic spacer.

I then connected a hose to the starboard side of the head (Outlet?) and back flushed, whole lot of calcium or salt? (White color) and debris came out the port side head (Outlet?).

I alternated back and forth until the water was clear on both back flushes. T

his also seems to fill the system down to the water pump as the hole drains on the lower unit ran steady also.

I have ordered a new thermostat kit and new hoses and snap clamps.

I read on the forum about the crossflow system and overheating possibly warping or swelling that...

So I am wondering if the back flush proves that system is working?

Do I dare run it with housing off just to check for flow through the motor?

Any other recommendations would be appreciated.

I have no idea if it ever overheated with prev owner I asked and of course he said no, but with no cam sleeve I don't think it had run recently he said about 16 months...

It does appear by the lost parts that he was tinkering and gave up when he could not get the lower unit off (didn't know about the pin under the carbs) so my guess is, it may have and he figured a new pump would solve it.

So today was the first start. It would not start where the prev owner had the throttle set.

In fact to get it to run I had to run the screw within 1/2 of the threads (Separate issue I am assuming).

Entire pump was replaced last week.

Using muffs, water streaming from the tell tale it has a weird brass fitting that has a larger hole than anything I have run with that has the plastic fittings, so it wasn't what I would call a strong stream but it was steady... and did get hot water at last check, not sure if it is supposed to or not.

Finally got 1000 RPMS and was using a thermal to monitor temps...

I was leery the thermostats might be salt crusted as it was left in the water by the prev owner.

Good thing I did... within about 1 minute the temp was at 165F (I was assuming it would run in the 140's) both heads then quickly went to 210F, (I heard the alarm at the same instant) and I quickly shut her down by disconnecting the kill switch connector at the power pack.

I monitored the heads after shut down and the maxed out at 217F

I pulled the thermostat head (No small task 1/64th turn at a time with a wrench on the 2 side ones lol), the thermostat gaskets were no where to be seen (Only anomaly in the unit) but it doesn't look close to as corroded as I assumed they would be. (pic)

Grommets were not swollen bypasses seemed to move freely. In the pic the only thing I cleaned was the black plastic spacer.

I then connected a hose to the starboard side of the head (Outlet?) and back flushed, whole lot of calcium or salt? (White color) and debris came out the port side head (Outlet?).

I alternated back and forth until the water was clear on both back flushes. T

his also seems to fill the system down to the water pump as the hole drains on the lower unit ran steady also.

I have ordered a new thermostat kit and new hoses and snap clamps.

I read on the forum about the crossflow system and overheating possibly warping or swelling that...

So I am wondering if the back flush proves that system is working?

Do I dare run it with housing off just to check for flow through the motor?

Any other recommendations would be appreciated.

I have no idea if it ever overheated with prev owner I asked and of course he said no, but with no cam sleeve I don't think it had run recently he said about 16 months...

It does appear by the lost parts that he was tinkering and gave up when he could not get the lower unit off (didn't know about the pin under the carbs) so my guess is, it may have and he figured a new pump would solve it.