Hi all,

I have been trying to repair a tilt trim issue with my '87 Johnson 50hp tilt and trim. The trim cylinders are the model with the cylinders on the outside of the engine used in the 70s and 80's. I bought the boat this past year and noticed the trim and tilt weren't functioning as they should. The motor tilts/trims out okay all the way up, but when I trim in there is heavy resistance and what appears to be a lot of back pressure in the cylinders (example: while trimming in the tilt cylinder outruns the trim cylinder causing a sort of binding, which slowly resolves after about 15 seconds). I disassembled and resealed both cylinders at this point and they both move easily and freely without any leaks. The system was reassembled and the same problem exists.

Looking into the valves now I find the check valves seals were bad and psuedo-following a forum by pnwboat, I replaced the check valve seats with small o-rings i had on hand (which did not working). I came across the parts I need to properly replace the seats (Briggs and Stratton Carburetor needle seat P/N:398188) and they should be here this weekend. Hopefully I am close to figuring this out.

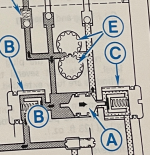

While I wait for the new valve seats I want to make sure shuttle/pump control piston is going to work properly. My concern is that my pump control piston doesn't look like any other one ive seen on the forums and there were no traces of an o-ring installed, which probably disintegrated long ago. As seen in the image, it does not have the same o-ring groove as many of the others ive seen on iboat.

My Piston and check valve:

Others Piston and check valve:

Is my black piston designed to be sealed with orings or have something different in those grooves? Any insight would be helpful.

I have been trying to repair a tilt trim issue with my '87 Johnson 50hp tilt and trim. The trim cylinders are the model with the cylinders on the outside of the engine used in the 70s and 80's. I bought the boat this past year and noticed the trim and tilt weren't functioning as they should. The motor tilts/trims out okay all the way up, but when I trim in there is heavy resistance and what appears to be a lot of back pressure in the cylinders (example: while trimming in the tilt cylinder outruns the trim cylinder causing a sort of binding, which slowly resolves after about 15 seconds). I disassembled and resealed both cylinders at this point and they both move easily and freely without any leaks. The system was reassembled and the same problem exists.

Looking into the valves now I find the check valves seals were bad and psuedo-following a forum by pnwboat, I replaced the check valve seats with small o-rings i had on hand (which did not working). I came across the parts I need to properly replace the seats (Briggs and Stratton Carburetor needle seat P/N:398188) and they should be here this weekend. Hopefully I am close to figuring this out.

While I wait for the new valve seats I want to make sure shuttle/pump control piston is going to work properly. My concern is that my pump control piston doesn't look like any other one ive seen on the forums and there were no traces of an o-ring installed, which probably disintegrated long ago. As seen in the image, it does not have the same o-ring groove as many of the others ive seen on iboat.

My Piston and check valve:

Others Piston and check valve:

Is my black piston designed to be sealed with orings or have something different in those grooves? Any insight would be helpful.