Bullie

Petty Officer 1st Class

- Joined

- Dec 20, 2014

- Messages

- 300

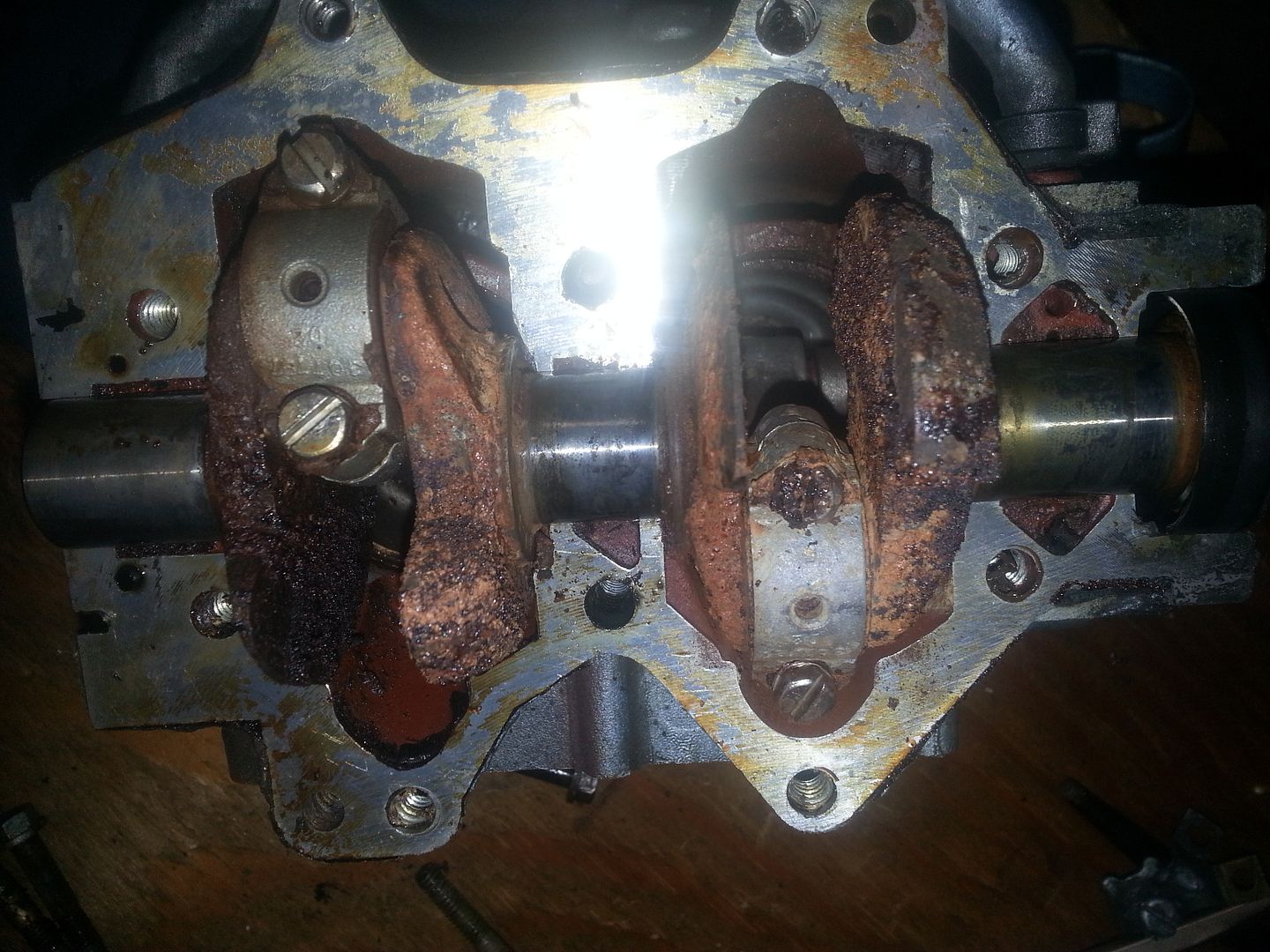

I bought a 6 hp Evinrude 6804B recently to see if I could get it running. It has good spark that will jump 1/2 inch on my testers. It had 110 lbs compression on the top cylinder and 60 on the bottom cylinder. I figured it was the head gasket and replaced it, smoothed the head on sandpaper over glass, put everything back together, torqued it down to specs, and checked compression again. This time I got 90 and 30. The cylinders looked really good. I saw no damage at all. But, there was a little sludgy looking stuff on the level of the gasket.

Will I have to take the power head off to view the pistons/rings? I assume that is what I should do next, check the rings?

Will I have to take the power head off to view the pistons/rings? I assume that is what I should do next, check the rings?