I've been using topics in these forums for the past 3 months and they have been very helpful. My son worked to save up and get a boat and motor this summer and we've made a project of fixing it up together. First time for either of us. With youtube and these forums, we feel like we've done a pretty good job. I'm at the end of my rope though. The issue we're having is that sometimes it won't stay running at low rpms, and most often to start, the handle needs to be rotated a little towards "fast" from "start". Sometimes if it dies after running for a while (when we slow down), it is extremely hard to get started again. Here's what we've done (in order):

- Replaced tank pickup

- new spark plugs (gapped correctly)

- replaced gas lines

- replaced fuel filter/pump

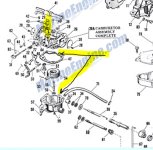

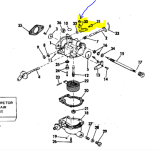

- rebuilt carb (including new low speed needle, gaskets, float, etc)

- new coils, points and condensers (gapped to 0.020)

- New impeller and seals

- new thermostat and gasket

- new head gasket (and lapped the head with piece of glass with emery cloth on it)