I don't have an answer to your woes, but here are a few tidbits of information.

Those keys should not be shearing. But they will if the parts are not right and assembled correctly. It may be true that friction holds the flywheel, not the key.

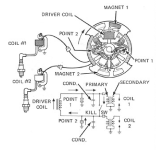

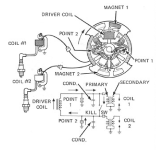

But the key positions the flywheel to the crankshaft. If the keyways are battered it will be difficult if not impossible to get it in the correct position. That affects the time that the magnets pass the driver coil. And that affects the time that the points break as related to the electrical charge in the driver. And that brings up the points cam. As the bulletin says, it is different than other motors, and more critical.

Back to the flywheel, the tapers must be smooth and true, and the hub must not be spread or cracked, and the shaft and flywheel must be clean and dry, and the nut must be torqued to 40-45 ft lbs. Some advocate lapping the taper, but I don't. And the keyways must not be battered. In short, a motor would not have left my shop unless all those conditions are met. Come-backs are expensive.