Michigan Lakes

Petty Officer 3rd Class

- Joined

- Dec 20, 2018

- Messages

- 86

Hi there guys. I've been kicking around the iBoats forums for a few months and have learned a great deal already. I had been spending quite a bit of time on The Hull Truth when I came across a post mentioning iBoats, Watermann and his rivet expertise. Needless to say, I found iBoats far more in tune with my strata of boat ownership.

I'll be a bit long-winded with this first post in order to get the back story out of the way.

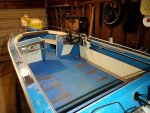

After a somewhat lengthy and very particular search (aluminum, 16', open bow, back-to-back seats, "running", OMC power, less than $2k) I found this boat on CL, and picked it up in Muskegon, MI in June 2018. The original asking price was $1800. When I met the owner at the boat launch, he could not keep the 70hp 3cyl Evinrude running under any sort of load. We ended up settling on $1100 based on his assumption that all three carburetors needed to be rebuilt. After some research and photo comparisons, it became quite apparent that the stator insulation had almost entirely melted off (see attached photo). A $50 used stator from ebay managed to solve the stalling under load issue. I'm not going to say the outboard runs like a Swiss watch now, but it's good enough to begin addressing structural and cosmetic issues.

To the best of my knowledge, I am the third owner. According to the second owner, the original owner had a habit of dropping his 20lb anchor directly on the bow floor after each use. Not surprisingly, that entire area was cratered and splintered. Additionally, there were multiple soft soft spots along the edges of the flooring.

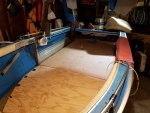

Last December, I spent a few evenings stripping the interior down to the hull. Needless to say, the floor was worse than I thought and the lower portions of the foam were entirely water logged. I am thankful that floor came out intact enough for template use. I had fairly good intentions of making some headway during the Winter months but the arctic temps we've experienced in SE Michigan would have made for wholly enjoyable hours in the unheated, detached garage.

I sprayed out the inside of the hull at the local coin wash last week and got the project back on track. Although I cannot find any damaged rivets and the hull did not appear to leak during the handful of lake trips it made last year. I have decided to apply a quart of Gluvit based on iBoats forum recommendations.

The plan is to maintain the open bow "speedboat" layout as comfortable seating for six is the primary reason I went with an open bow vessel. It seems like Starcraft intended for the design to serve a number of purposes. Fish-able, ski/tube-able, trailer-able, semi-comfortable, and standard 20' garage-able it is.

If and when I do fish, it's a pretty casual sort of thing that's more about beer and conversation as opposed to stocking my deep freezer. Swimming, tubing, shore cruising, and WOT runs are what I really enjoy.

I plan on using carpet instead of the original (vinyl?) floor covering. Additionally, I'd like to replace the hard, fixed bow area seating surfaces with padded, removable cushions that will allow greater access to the storage area. I'm not sure there's such a thing as too much storage on any small boat.

I'll be a bit long-winded with this first post in order to get the back story out of the way.

After a somewhat lengthy and very particular search (aluminum, 16', open bow, back-to-back seats, "running", OMC power, less than $2k) I found this boat on CL, and picked it up in Muskegon, MI in June 2018. The original asking price was $1800. When I met the owner at the boat launch, he could not keep the 70hp 3cyl Evinrude running under any sort of load. We ended up settling on $1100 based on his assumption that all three carburetors needed to be rebuilt. After some research and photo comparisons, it became quite apparent that the stator insulation had almost entirely melted off (see attached photo). A $50 used stator from ebay managed to solve the stalling under load issue. I'm not going to say the outboard runs like a Swiss watch now, but it's good enough to begin addressing structural and cosmetic issues.

To the best of my knowledge, I am the third owner. According to the second owner, the original owner had a habit of dropping his 20lb anchor directly on the bow floor after each use. Not surprisingly, that entire area was cratered and splintered. Additionally, there were multiple soft soft spots along the edges of the flooring.

Last December, I spent a few evenings stripping the interior down to the hull. Needless to say, the floor was worse than I thought and the lower portions of the foam were entirely water logged. I am thankful that floor came out intact enough for template use. I had fairly good intentions of making some headway during the Winter months but the arctic temps we've experienced in SE Michigan would have made for wholly enjoyable hours in the unheated, detached garage.

I sprayed out the inside of the hull at the local coin wash last week and got the project back on track. Although I cannot find any damaged rivets and the hull did not appear to leak during the handful of lake trips it made last year. I have decided to apply a quart of Gluvit based on iBoats forum recommendations.

The plan is to maintain the open bow "speedboat" layout as comfortable seating for six is the primary reason I went with an open bow vessel. It seems like Starcraft intended for the design to serve a number of purposes. Fish-able, ski/tube-able, trailer-able, semi-comfortable, and standard 20' garage-able it is.

If and when I do fish, it's a pretty casual sort of thing that's more about beer and conversation as opposed to stocking my deep freezer. Swimming, tubing, shore cruising, and WOT runs are what I really enjoy.

I plan on using carpet instead of the original (vinyl?) floor covering. Additionally, I'd like to replace the hard, fixed bow area seating surfaces with padded, removable cushions that will allow greater access to the storage area. I'm not sure there's such a thing as too much storage on any small boat.

Attachments

Last edited: