jay_merrill

Vice Admiral

- Joined

- Dec 5, 2007

- Messages

- 5,653

I've been thinking of putting a tell tale in my old Johnson for some time, but didn't want to take the time to pull the head to do it. While I do realize that some people install the nipple blindly, using grease on the drill and tap to prevent shavings from getting into the cooling system, I have never been comfortable drilling into something that I can't see. I'm also aware of a thread here (http://forums.iboats.com/showthread.php?t=222677) that provides an OMC service bulletin on moving the nipple location in 3 cylinder motors, but was reluctant to follow it, because it applies to motors of a different year. As it turns out, its a good thing I was not comfortable using this info, because the crankcase on my motor is different.

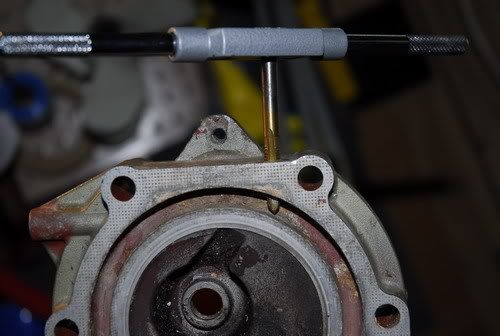

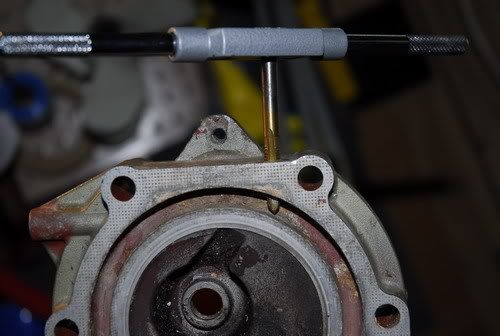

Instead, I decided to pull the head on my motor. It made sense to do this because I had the powehead off of the motor, while repairing a broken swivel bracket. I chose to install a nipple in the highest point of the water passage in the head, and here is how I did it.

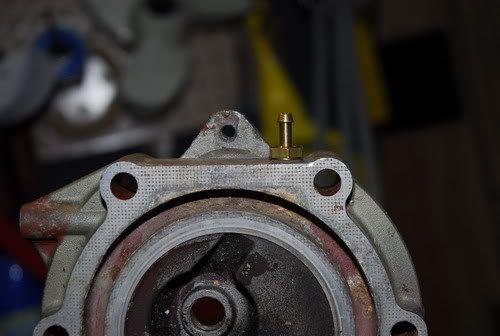

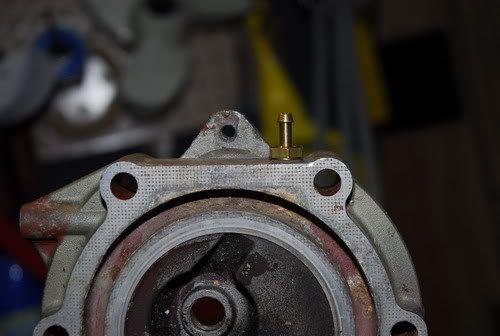

First, I had to find a nipple that was small enough to work in the head. This was somehwat of a challenge because the water passage is only 1/2" deep, and the smallest brass elbow that I could find was too big. The problem was the threaded portion, not the actual nipple. What I ended up using is actually a carburetor part - the nipple is OMC/BRP Part #326467. This idea came from my local OMC/BRP dealer, who also advised me not to follow the service bulletin referenced above.

I opted to place the nipple in an offset position, so that it wouldn't interfere with using the lifting bracket on the motor. I had originally intended to run the water tube down the port side of the motor, but that ended up not working well, due to the location that I chose for the tell tale outlet. Of course, Murphey's law being what it is, I discovered this after installing the nipple. All is well. however, because the installation works just fine.

I used a #7 drill & tap (1/4-20) to drill/thread the hole, after center punching a starting point 5/16" in from the edge of the head. As I mentioned before, the water passage is 1/2" deep, so 1/4" (4/16") is the midpoint, but an extra 16" was need to make sure that the hex head base of the nipple, would be clear of the edge of the head. The nipple was seated with heat resistent thread sealer and a crush washer.

There are other places that a nipple could be installed, including in the crankcase, but I opted to go with the head, because I felt like doing so would be a lot easier to remedy if I made a mistake. Simply put, its much easier to go find another head for this motor than it is to find a usable crankcase, not to mention pulling the thing apart!

I also want to get to the highest point possible to deal with the air pocket issue mentioned in the service bulletin. Once again, that bulletin is for another motor, but the air issue would be expected to be the same. Given that my tell tale now sputters water/air, before issuing a steady stream of water, I think the choice in location was the correct one.

I also used rubber hose from an auto parts store, rather than the refrigerator tubing that some people use. The reason why I did so, is because the hose must make an immediate bend at the nipple, in order to clear the air intake box inside of the motor's cowl. The problem with the refrigerator tube is that it is too stiff, and collapses if you try to bend it too sharply. Frankly, an elbow would have been a better fitting for this job, but as I said before, I couldn't find one small enough. All is OK on this issue, though - the rubber tube works well.

Here are some photos to better illustrate what I did.

Instead, I decided to pull the head on my motor. It made sense to do this because I had the powehead off of the motor, while repairing a broken swivel bracket. I chose to install a nipple in the highest point of the water passage in the head, and here is how I did it.

First, I had to find a nipple that was small enough to work in the head. This was somehwat of a challenge because the water passage is only 1/2" deep, and the smallest brass elbow that I could find was too big. The problem was the threaded portion, not the actual nipple. What I ended up using is actually a carburetor part - the nipple is OMC/BRP Part #326467. This idea came from my local OMC/BRP dealer, who also advised me not to follow the service bulletin referenced above.

I opted to place the nipple in an offset position, so that it wouldn't interfere with using the lifting bracket on the motor. I had originally intended to run the water tube down the port side of the motor, but that ended up not working well, due to the location that I chose for the tell tale outlet. Of course, Murphey's law being what it is, I discovered this after installing the nipple. All is well. however, because the installation works just fine.

I used a #7 drill & tap (1/4-20) to drill/thread the hole, after center punching a starting point 5/16" in from the edge of the head. As I mentioned before, the water passage is 1/2" deep, so 1/4" (4/16") is the midpoint, but an extra 16" was need to make sure that the hex head base of the nipple, would be clear of the edge of the head. The nipple was seated with heat resistent thread sealer and a crush washer.

There are other places that a nipple could be installed, including in the crankcase, but I opted to go with the head, because I felt like doing so would be a lot easier to remedy if I made a mistake. Simply put, its much easier to go find another head for this motor than it is to find a usable crankcase, not to mention pulling the thing apart!

I also want to get to the highest point possible to deal with the air pocket issue mentioned in the service bulletin. Once again, that bulletin is for another motor, but the air issue would be expected to be the same. Given that my tell tale now sputters water/air, before issuing a steady stream of water, I think the choice in location was the correct one.

I also used rubber hose from an auto parts store, rather than the refrigerator tubing that some people use. The reason why I did so, is because the hose must make an immediate bend at the nipple, in order to clear the air intake box inside of the motor's cowl. The problem with the refrigerator tube is that it is too stiff, and collapses if you try to bend it too sharply. Frankly, an elbow would have been a better fitting for this job, but as I said before, I couldn't find one small enough. All is OK on this issue, though - the rubber tube works well.

Here are some photos to better illustrate what I did.