GoodMr1967

Cadet

- Joined

- Oct 1, 2016

- Messages

- 10

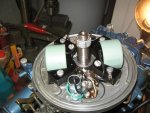

Hello. I just got a little 10 hp Evinrude with a 12' aluminum boat for some lake fishing next spring. The seller said it had been 10 years since he had run her, but he figured she should still run. I got her in a barrel of water with some fresh gas (there was 10 year old gas still in the tank:  ) and pulled the cord. She started up, a bit rough, but ran for about 5 minutes and quit. There was water flow from the outlet while running. Once the motor quit, I couldn't restart it until all was cool again: more than 1 hour. Out of curiosity, I checked the compression and found a whopping 55 psi in each piston! Looked like a great time to pull the head and see what was inside. You can see the results in the photo below - someone didn't flush

) and pulled the cord. She started up, a bit rough, but ran for about 5 minutes and quit. There was water flow from the outlet while running. Once the motor quit, I couldn't restart it until all was cool again: more than 1 hour. Out of curiosity, I checked the compression and found a whopping 55 psi in each piston! Looked like a great time to pull the head and see what was inside. You can see the results in the photo below - someone didn't flush  blue

blue . I am imagining that this project is going to be in depth, but that could be a fun time with my three sons at the workbench with me. Now, for the questions:

. I am imagining that this project is going to be in depth, but that could be a fun time with my three sons at the workbench with me. Now, for the questions:

1. Are there water passages that I will not be able to clean sufficiently?

2. What is the best method to clean the passages and get to cool running?

3. Is there a chance that new rings could remedy the compression problems?

4. Am I looking at Don Quixote's "Impossible dream" that this motor will run reliably again?

Thanks for any input you can send.

Having trouble uploading photo: basically, water ports are heavily clogged with salt around lower cylinder and ends of pistons are pretty black. I have also disassembled the thermostat and it is shot (as expected).

1. Are there water passages that I will not be able to clean sufficiently?

2. What is the best method to clean the passages and get to cool running?

3. Is there a chance that new rings could remedy the compression problems?

4. Am I looking at Don Quixote's "Impossible dream" that this motor will run reliably again?

Thanks for any input you can send.

Having trouble uploading photo: basically, water ports are heavily clogged with salt around lower cylinder and ends of pistons are pretty black. I have also disassembled the thermostat and it is shot (as expected).