Looks like you have this type of T&T. If it is, note the following terminologies:

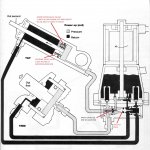

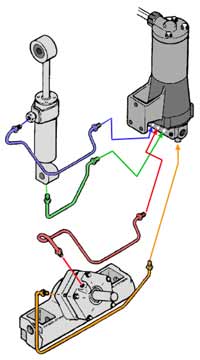

Upper (or raise) trim or tilt lines refer to hydraulic lines that connect from the Valve Body to the bottom of each cylinder, i.e. trim or tilt.

Lower trim or tilt lines refer to hydraulic lines that connect from the Valve Body to the top of the each cylinder.

Valve Body (VB) is the actual pump that houses both the pump and the check valves (shuttle valve and two spool valves)

Since the trim cylinder works but not the tilt cylinder, here's a test you can do to isolate the problem:

You will need a 3/16” brass cap and also a 3/16” plug. Both are available at Ace Hardware or some auto stores.

Step 1: Test the tilt cylinder for leak down

- Raise the tilt cylinder fully and then support the motor with a suitable block

- Relieve pressure by slightly tilting down, MAKE SURE THIS STEP IS DONE BEFORE CONTINUING!!!

- Disconnect “raise” line from pump assembly connecting to the bottom of tilt cylinder

- Cap line with the female brass cap and also the valve body port

- Remove block support from gearcase

- Mark across the swivel and stern bracket with a marker to note movement. This may take a few minutes to about 30 minutes to see movement or leak down

- If leak down is noted, replace tilt cylinder or in your case rebuild it.

Since in your case the tilt cylinder will not come up, try manually raising the motor by having someone push the UP button while you manually raise the motor. If motor raises, continue placing a support block of wood to hold motor in place.