Definitely treat the wood once you have it shaped and the drainage/air holes drilled. You can mix up a wood sealer often referred to on this forum . . .

Old timers wood sealer (OTWS)

While you are at it, you might want to take a look at the rest of your seats to see if they need some attention/replacement as well.

- 1/3 Polyurethane

- 1/3 Linseed oil

- 1/3 Mineral spirits

Is that polyurethane varnish? Edible / raw / boiled linseed oil? Does it leave the wood soft enough to allow staples to go in easier than epoxied wood?

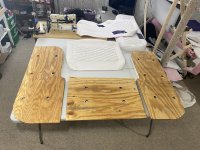

I cut the new plywood to shape and size today, placed the old wood on top of the new and traced around the less rotten side that still has the original shape, the rotten side has chunks rotted out so I spun it around and upside down to trace the original shape to the other side of the new wood. Cutting it out with the jigsaw was easier than I expected, didn't get it perfect but it should be good enough considering it'll be covered with foam and vinyl anyway. Rounded the edges and cleaned them up a bit with the sander. The position of the holes where the Tnuts were fitted in the old wood is vague due to the rot so I'll need to come up with a way to make sure I get the Tnuts in the correct position, the hinges were screwed into the boat fibreglass and I don't want to have to make new holes in the boat.

I'll check the other seats but I think they're fine. I think this trim has been kept wet much of the time because the boat trailer cover touches it, rain soaks through the cover where it touches, especially before I re-treated the cover with Fabsil.

Which reminds me, I need to get the trailer cover fixed or by another. The material around the edges that has the press-studs is separating from the rest of the canvas, seems the stitching has had too much sun and weather exposure in the past but I made it worse last year by putting it through the washing machine, wanted to wash it before spraying it with Fabsil. Wonder if any firm still makes a good fitting trailer cover for a '95 Four Winns Sundowner 205 and how much it'd cost. One of my customers said he repairs canvas covers, might ask him to fix mine. I also want to get a couple of spare wheel bearings for the 4 wheel trailer but I don't know the spec of the bearings yet, I might remove a hub and take it to a bearing company to see if they can identify and supply. I'd better remove the drive, check bellows, gimble bearing and alignment, regrease UJ's this year, didn't do it last year.