Hi guys, i'm sorry for my not so good english, i'm italian!

I need a help for the new floor structure of my boat: i bought a used boat and now i'm restructuring it.

under the floor panel the old structure was like this:

I cut and removed the central beam (the wood inside was rotten) and those 4 sleepers (the entire structure was soaked in water and so f*****g heavy).

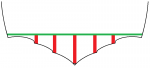

now i have the "naked" hull and i have to design a new structure (lighter than the old one), my idea was like this:

with a 210cm long central beam and 5 of those transversal panels (i drew only one edge of them) but i don't know the materials, their thickness and if it's a good idea, can anyone help me?

thanks a lot!

I need a help for the new floor structure of my boat: i bought a used boat and now i'm restructuring it.

under the floor panel the old structure was like this:

I cut and removed the central beam (the wood inside was rotten) and those 4 sleepers (the entire structure was soaked in water and so f*****g heavy).

now i have the "naked" hull and i have to design a new structure (lighter than the old one), my idea was like this:

with a 210cm long central beam and 5 of those transversal panels (i drew only one edge of them) but i don't know the materials, their thickness and if it's a good idea, can anyone help me?

thanks a lot!