redfury

Commander

- Joined

- Jul 16, 2006

- Messages

- 2,655

Re: pics of my boat project

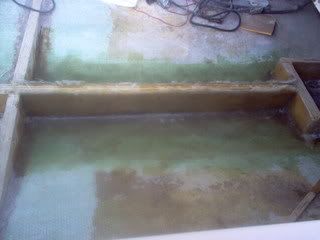

Looks like you need to deal with drainage back to the bilge still. Seems that nobody does this initially

I'd think make sure the drain areas were established in the wood before I started adhering anything to the hull, and properly sealed. The problem is getting the water to the bilge and OUT of the boat in the first place, isn't it?

Looks really good though. I'm definitely going to get my stringers done this year.

Looks like you need to deal with drainage back to the bilge still. Seems that nobody does this initially

I'd think make sure the drain areas were established in the wood before I started adhering anything to the hull, and properly sealed. The problem is getting the water to the bilge and OUT of the boat in the first place, isn't it?

Looks really good though. I'm definitely going to get my stringers done this year.