The main stringers, at least the two that ran from the transom forward for approximately 12 feet, were made up of a 3/4" wide piece of wood, not plywood, and were 4" high. There was an additional strip, what I would call a cleat, also 3/4" wide, attached to the side even with the top of the main stringers.

The center stringers "yellow" were just there I believe to outline/support the area for the ski locker and maybe support the deck slightly. The deck was attached to the main stringers "red" with staples. Actually all the wood was attached to other wood with staples and most of the staples were rusted and had deteriorated.

Here it all is with the deck removed. Not a very pretty sight.

The center stringers were I believe 1/2" thick plywood and about 7" high.

However they were so rotten, I am actually guessing at the thickness.

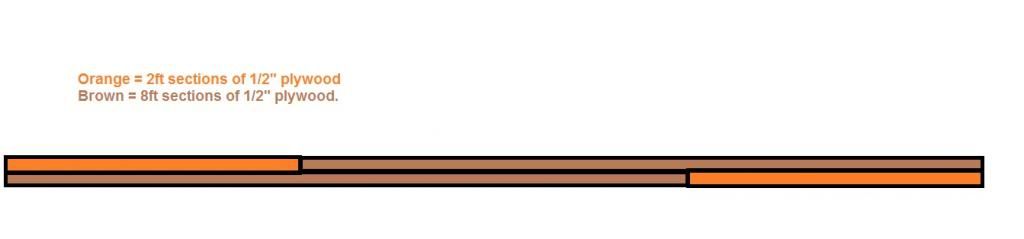

What I am considering is making the main stringers a total of 1" thick, using two 1/2" thick pieces of plywood approximately 4" high, joined with Titebond III or PB, and of course offsetting the joints. I believe the new main stringers will be stronger than the originals. Also, making the center stringers 3/4" thick instead of the 1/2" thick of the originals.

Anyone care to share their thoughts, knowledge, experience etc., Thanks for any and all input.