Daniel1947

Petty Officer 1st Class

- Joined

- Sep 22, 2010

- Messages

- 267

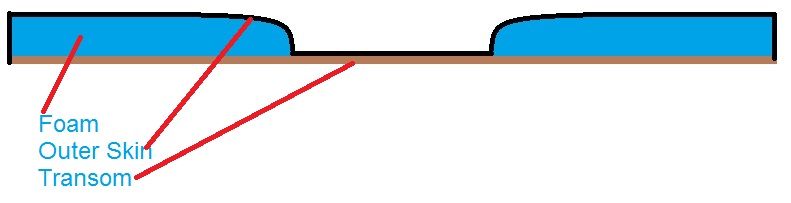

I am sure there are enough photos of rotten decks, stringers and transoms on the forum; however, if anyone wants to see mine, I will post them. For now I would just like to post the photos showing my area of concern as I continue rebuilding my 89 Astro Quickfire 18FS. I have already removed the cap and cut out decking and stringers; I haven’t really started the grinding yet but have done some. My area of concern at this point is the transom.

I have removed the main stringers to within a few inches of the transom. I drilled holes near the bottom of the transom as is indicated by the “YELLOW” circles. Even though the stringers and deck was pretty rotten, and the foam was still wet, all I seemed to get off the drill bit was “dry” powder wood. I must also add it was very hard, drilling into the transom, so I am having my doubts if the transom will need to be replaced.

I have removed the main stringers to within a few inches of the transom. I drilled holes near the bottom of the transom as is indicated by the “YELLOW” circles. Even though the stringers and deck was pretty rotten, and the foam was still wet, all I seemed to get off the drill bit was “dry” powder wood. I must also add it was very hard, drilling into the transom, so I am having my doubts if the transom will need to be replaced.