jmink

Seaman

- Joined

- Jan 27, 2014

- Messages

- 64

Tri-Hulls due to the hulls configuration tend to hold their shape much better than a v-hull.

I agree with Wood on this one! I took the floor and stringers out of mine last fall and have pulled it to and from the shop a dozen times, sat outside all winter under a tarp on an old roller trailer. Since I had some hull work to do anyway, I wasn't real concerned. Just for grins, I looked over the hull this past weekend and took some measurements and they are exactly as they were when I first took them last fall.

These older boats usually had some pretty thick glass on them and the cathedrals in the hull just make them pretty rigid.

One thing different though, my hull cap is still attached making it a little more stable. I only cut the cap at the stern to get to the transom.

Looking good so far!

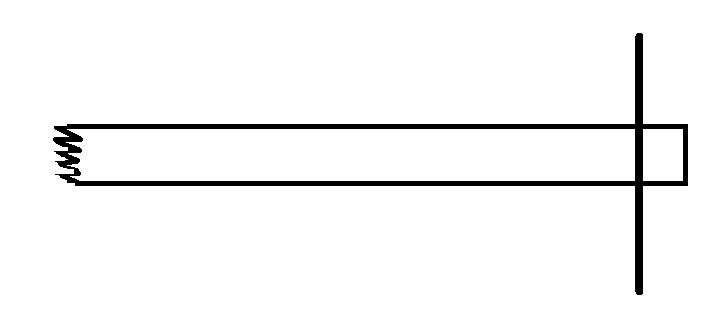

Oh, BTW, mine had a hidden drill bit treasure too! Mine was grinning out through the bottom of the hull in the bilge and encased in resin.

BTW, when you get around to removing the glue residue on the sides, M.E.K. is your huckleberry.

The foam boxes, not only provide additional flotation, but are also somewhat structural in nature. I'd advise you to seriously consider replacing them as they are.

I would just clean them up and paint them later if the foam isn't too waterlogged.

get a 2" pc of PVC @ 2ft long

cut teeth in one end & use it as a boring bit to drill down thru the foam until you contact the hull. Remove the core sample of foam & watch for the bore hole to refill w/ water. If the bore sample is wet, discolored or smells funky, the foam has been compromised & should be removed & replaced.

It happens fairly often that all outward signs suggest sound, uncompromised foam, but once you core it or start to remove it, it is in fact waterlogged, the hard exterior shell just made it appear to be sound.

Re: 1973 Glastron V-156 Sportster Floor/Stringer Restoration

Looking good. If at all possibile, resist the urge to remove all the sringers at the same time. If you replace all the stringers except the center one, then remove and replace it after the outboard stringers are in, the chances of the hull being deformed are greatly decreased.

When I redid my stringers, I didnt put "notches" in them for the 1"x4" that was used to bridge the seams in the plywood floor. I just taped the edges of the plywood from the top with several layers of 6" fiberglass tape and it worked well. If you want to use gellcoat instead of carpet for the floor, it would mean that you would have more work with the fairing the deck, but it might still be worth it.

Good Work!!!

Thanks again for making and sharing the videos...they will really be helpful to the ones following behind us, to see what lies ahead...great job!

Progress is looking fantastic and at this rate, you'll be in the home stretch in no time!