emerson281

Cadet

- Joined

- Feb 17, 2013

- Messages

- 7

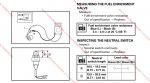

I have a 1999 Yamaha 115HP (C115TLRX). It has an electric choke (solenoid) that is activated by pushing the key in as you have the key turned into the start position. It is a momentary switch; as soon as you let up on the key, the choke returns to the normal position.

The problem is that when I push in on the key, the solenoid that is supposed to choke the two carbs by lifting some linkage up doesn't seem to have the power to do so. I see the plunger on the solenoid trying to raise up into the body of the solenoid and it does move a little bit, but it's just not strong enough to lift the linkage to active the chokes.

When I move the choke linkage manually; by hand directly at the linkage or by the manual level at the front base of the cowling, it moves smoothly and doesn't at all seem bound up or otherwise impeded...the solenoid should have no problem lifting the linkage into the choked position.

So, before I buy a solenoid assembly, is there some sort of troubleshooting method that I can use to verify that it needs to be replaced?

I plan to make sure that the ground wire for the solenoid is good and then check the voltage at the solenoid when the key is pushed in (although I'm not really sure what that reading should be...I'm guessing 6 or 12 V). I feel I should check the ignition switch as well, but it seems to me that if something is happening at the solenoid when the key is pushed in, then the ignition switch probably doing it's job....right?

I would really appreciate any guidance on how to proceed...I feel like I'm overlooking something.

Thanks,

Shane

The problem is that when I push in on the key, the solenoid that is supposed to choke the two carbs by lifting some linkage up doesn't seem to have the power to do so. I see the plunger on the solenoid trying to raise up into the body of the solenoid and it does move a little bit, but it's just not strong enough to lift the linkage to active the chokes.

When I move the choke linkage manually; by hand directly at the linkage or by the manual level at the front base of the cowling, it moves smoothly and doesn't at all seem bound up or otherwise impeded...the solenoid should have no problem lifting the linkage into the choked position.

So, before I buy a solenoid assembly, is there some sort of troubleshooting method that I can use to verify that it needs to be replaced?

I plan to make sure that the ground wire for the solenoid is good and then check the voltage at the solenoid when the key is pushed in (although I'm not really sure what that reading should be...I'm guessing 6 or 12 V). I feel I should check the ignition switch as well, but it seems to me that if something is happening at the solenoid when the key is pushed in, then the ignition switch probably doing it's job....right?

I would really appreciate any guidance on how to proceed...I feel like I'm overlooking something.

Thanks,

Shane