achris

More fish than mountain goat

- Joined

- May 19, 2004

- Messages

- 27,468

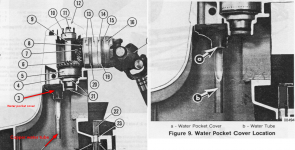

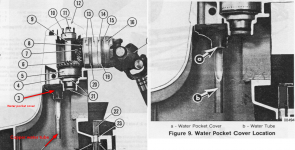

WATER POCKET COVER.

What is it, where is it and why is it important.

The water pocket cover is located in the bottom of the drive shaft housing, at the top of the exhaust cavity, of all MC-1, R, MR and Alpha One drives. It’s a plastic cover that has the copper tube from the water pump going into it. It assists the cooling of the lower side of the drive shaft housing and is the conduit for the water through the drive shaft housing to the bell housing and then on to the engine.

Alpha One Gen II drives have a water pocket, but it’s cast as part of the housing, and as such has done away with all the problems I will discuss here.

What’s the problem with the plastic water pocket cover?

As the cooling water from the engine exits the exhaust elbow(s), it mixes with and cools the exhaust gases. When the engine runs without cooling water because of, for example picking up excess seaweed or a plastic bag, or the flushers falling off or you forgetting to turn the water tap on (yes, it’s been done), the exhaust gases don’t get cooled before entering the drive. The exhaust gases are hot enough to soften and distort the plastic cover and sometimes blister it. When that happens the gasket surfaces of the cover are no longer straight and begin leaking.

The issue with the gaskets leaking only shows up at higher engine speeds and loads. While the engine is idling or at lower speed, the volume of water from the water pump is usually enough to maintain enough water volume on the inside of the water pocket cover to stop any exhaust gases pushing beyond the gasket. When the engine load increases, the exhaust gas pressure inside the drive also increases. It then starts to push into the water cover and mixes with the fresh cooling water coming into the engine. This reduces the cooling efficiency (by warming the water) and reducing the water volume available to cool the engine, at the very time the engine needs the most cooling.

How to test for a leaking water pocket cover.

There are a couple of ways of testing the water pocket cover for leaks.

One way is to put a section of clear hose between the water inlet fitting on the transom plate and the engine thermostat housing, or wherever the water comes into the engine from the drive. You then need to go out and run the engine up under load. This test can’t be done on flushers, or even in the water at idle or revving the engine without load, so you are going to need 2 people. If you see bubbles in the clear hose, the water pocket cover is most likely leaking (you can pick up air around the base of the water pump if that gasket isn’t sealing properly).

Also, at each annual service I look at the plastic cover. If there is any sign of heat stress, there’s a 99% chance the cover is distorted, and the gasket WILL be leaking. To pressure test the cover I invert the drive shaft housing (this test must be done with the drive split), plug the water tube hole in the cover (with a rag or something similar), spray some soapy water around the gasket area of the cover, then gently blow compressed air in through the passage at the front of the drive shaft housing (with the air line sealed as best as possible with a rag or such). If you see soapy bubbles around the plastic cover, it’s leaking and must be replaced.

Removing the old cover.

Removing the old cover is not as easy as it sounds. The cover is held in by 4 x ¼”UNC stainless steel screws, and there's the problem. Stainless screws in an aluminium housing, in seawater, is only going to end one way. They have a propensity to break off when you attempt to remove them. I usually find a liberal dose of oxygen and acetylene to help. I first use a bar or chisel to break up and remove the old cover and leave the screws to be dealt with without the cover in the way. If you can cycle heating and cooling of the screws it dries out the products of corrosion that are holding them in, you may get them to loosen up. You can also try leaving a penetrating oil on them overnight. If you still can’t remove them, then they will shear off. At this point it may be worth a trip to the local machine shop to get them to drill and remove the remnants. (Maybe call the shop before you break them and see if they would prefer to deal with them intact.) If you wish to tackle getting the broken off bolt out yourself, you are going to need to drill VERY ACCURATELY the centre of the screw and re-tap it. I do not suggest using ‘easi-outs’. All they do is spread the bolt in the hole and make it even tighter, then break off themselves, leaving you with a piece of hardened steel to deal with.

When you are putting the new cover on, the torque on the screws is 30-40 inch-pounds (about 3 ft-lbs). Over-tightening will distort the cover, and you're back to square one. Use a non-hardening gasket sealer on the gasket (like Perfect Seal or perm-a-gasket).

So, there you have it, water pocket cover 101…

Chris………..

What is it, where is it and why is it important.

The water pocket cover is located in the bottom of the drive shaft housing, at the top of the exhaust cavity, of all MC-1, R, MR and Alpha One drives. It’s a plastic cover that has the copper tube from the water pump going into it. It assists the cooling of the lower side of the drive shaft housing and is the conduit for the water through the drive shaft housing to the bell housing and then on to the engine.

Alpha One Gen II drives have a water pocket, but it’s cast as part of the housing, and as such has done away with all the problems I will discuss here.

What’s the problem with the plastic water pocket cover?

As the cooling water from the engine exits the exhaust elbow(s), it mixes with and cools the exhaust gases. When the engine runs without cooling water because of, for example picking up excess seaweed or a plastic bag, or the flushers falling off or you forgetting to turn the water tap on (yes, it’s been done), the exhaust gases don’t get cooled before entering the drive. The exhaust gases are hot enough to soften and distort the plastic cover and sometimes blister it. When that happens the gasket surfaces of the cover are no longer straight and begin leaking.

The issue with the gaskets leaking only shows up at higher engine speeds and loads. While the engine is idling or at lower speed, the volume of water from the water pump is usually enough to maintain enough water volume on the inside of the water pocket cover to stop any exhaust gases pushing beyond the gasket. When the engine load increases, the exhaust gas pressure inside the drive also increases. It then starts to push into the water cover and mixes with the fresh cooling water coming into the engine. This reduces the cooling efficiency (by warming the water) and reducing the water volume available to cool the engine, at the very time the engine needs the most cooling.

How to test for a leaking water pocket cover.

There are a couple of ways of testing the water pocket cover for leaks.

One way is to put a section of clear hose between the water inlet fitting on the transom plate and the engine thermostat housing, or wherever the water comes into the engine from the drive. You then need to go out and run the engine up under load. This test can’t be done on flushers, or even in the water at idle or revving the engine without load, so you are going to need 2 people. If you see bubbles in the clear hose, the water pocket cover is most likely leaking (you can pick up air around the base of the water pump if that gasket isn’t sealing properly).

Also, at each annual service I look at the plastic cover. If there is any sign of heat stress, there’s a 99% chance the cover is distorted, and the gasket WILL be leaking. To pressure test the cover I invert the drive shaft housing (this test must be done with the drive split), plug the water tube hole in the cover (with a rag or something similar), spray some soapy water around the gasket area of the cover, then gently blow compressed air in through the passage at the front of the drive shaft housing (with the air line sealed as best as possible with a rag or such). If you see soapy bubbles around the plastic cover, it’s leaking and must be replaced.

Removing the old cover.

Removing the old cover is not as easy as it sounds. The cover is held in by 4 x ¼”UNC stainless steel screws, and there's the problem. Stainless screws in an aluminium housing, in seawater, is only going to end one way. They have a propensity to break off when you attempt to remove them. I usually find a liberal dose of oxygen and acetylene to help. I first use a bar or chisel to break up and remove the old cover and leave the screws to be dealt with without the cover in the way. If you can cycle heating and cooling of the screws it dries out the products of corrosion that are holding them in, you may get them to loosen up. You can also try leaving a penetrating oil on them overnight. If you still can’t remove them, then they will shear off. At this point it may be worth a trip to the local machine shop to get them to drill and remove the remnants. (Maybe call the shop before you break them and see if they would prefer to deal with them intact.) If you wish to tackle getting the broken off bolt out yourself, you are going to need to drill VERY ACCURATELY the centre of the screw and re-tap it. I do not suggest using ‘easi-outs’. All they do is spread the bolt in the hole and make it even tighter, then break off themselves, leaving you with a piece of hardened steel to deal with.

When you are putting the new cover on, the torque on the screws is 30-40 inch-pounds (about 3 ft-lbs). Over-tightening will distort the cover, and you're back to square one. Use a non-hardening gasket sealer on the gasket (like Perfect Seal or perm-a-gasket).

So, there you have it, water pocket cover 101…

Chris………..

Last edited: