jpwilly

Petty Officer 3rd Class

- Joined

- Jun 15, 2011

- Messages

- 95

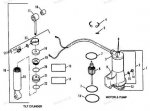

EDIT: There is an issue with my Trim Cylinder. The tilt works great moves the motor up and down as it should but bottoms out on the trim ram. The ram sticking out but won't retract.

I need help don't know where to start...I posted pictures below.

I need help don't know where to start...I posted pictures below.

Last edited: