Donald0039

Chief Petty Officer

- Joined

- Jun 11, 2022

- Messages

- 401

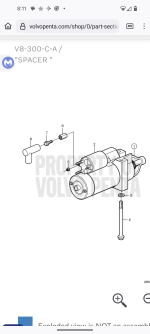

I have a new VP #3885317 starter but cannot get the bolts off the old starter. With a 6 pt socket and ratchet wrench handle. At 70 maybe just not strong enough.

I will spray PB Blaster on the bolt head but still concerned about snapping a bolt if it's corroded at the threads. The bolts is 4" or so long.

Considering buying a compact cordless impact as I think a better chance of getting the bolts out without snapping than a breaker bar.

I will spray PB Blaster on the bolt head but still concerned about snapping a bolt if it's corroded at the threads. The bolts is 4" or so long.

Considering buying a compact cordless impact as I think a better chance of getting the bolts out without snapping than a breaker bar.