Watermann

Starmada Splash of the Year 2014

- Joined

- Jan 12, 2013

- Messages

- 13,785

All of us have to learn a new trade when it comes to restoring our 'gently used' riveted aluminum boats. Disputably Starcraft boats are the most popular and prolific aluminum boat of all time and the same rivet questions come up time and time again. Rather than answer each and every question each time, multiple times a year I decided to do it all at once and create this rivet thread. This is not the definitive tell all about rivets just what I have learned working with these older riveted boats.

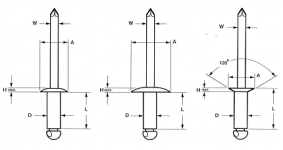

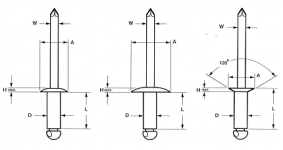

There are 2 types of rivets in 2 diameter sizes most commonly found on these boats. Solid rivets and blind rivets. Diameter sizes 3/16 in and 5/32 in. Some call blind rivets 'pop' rivets. From here on out I'll refer to them as blinds or solids. Each type of rivet be it either solid or blind come in several different types. I will try to demystify these subtle differences.

Solids:

The solid rivet is most commonly used to attach structural elements of the boat and of course is used to connect each of the separate panel seams of the boat. The most commonly used solids in your boat will be as follows.

Head: Brazier

Diameter: 3/16 in and 5/32 in

Length: Determined by the number of layers being fastened. Aluminum thickness common to the older riveted Starcraft boats.

Hull sides .080

Bottom and Ribs: .090

Transom .100

Gunnels and bow cover .065

I recommend having lengths of 3/8” for 2 layers and 7/16” for 3 layers on hand for your project. I personally would replace all structural solid rivets with 3/16 in.

Solid rivet material: Without getting into any arguments over metallurgy from those reading, here are the solids commonly found online in the correct diameter. 1100F which is pure soft aluminum and 2117T4 which is a strong alloy. The hull AL material is 5052 alloy. I would not recommend using 1100F pure soft AL on structural components such as the ribs.

Some tools of the trade when solid riveting.

Air Hammer

Rivet set 3/16" dia brazier head:

Bucking bar:

Clecos:

Very useful is holding pieces together that are to be fastened.

Blind Rivets:

Dome head blind:

The gunnels and bow cover are held on by 5/32" blinds in .126 - .187 grip range. The splashwell on my SS I used solids to attach it's splashwell and the consoles to the gunnels. If you use blinds I recommend 3/16" dia blinds for the splashwell and consoles and you may have to increase length in some cases to the next grip range. It never hurts to have multiple sizes as no two boat models are the exactly the same.

Large flange blind:

The decking is secured using the 3/16" LF blinds. Grip range is determined by how thick of plywood you'll be using for your decking.

1/2" and 5/8 in decking: 3/16 in diameter with a grip range of .625 - .875. If you're counter sinking the heads in order to lay carpet or vinyl deck covering over the installed decking then you'll want to drop to the next lower grip range (.501-.625) if using 1/2" plywood decking but that range listed above will work for 5/8 in ply.

3/4" plywood decking use the 3/16 in diameter with a .876-1.00 grip range. Also again if counter sinking the heads you could drop to the next lower grip range (.625-.875) For counter sinking I use a drill guide to get the exact depth desired on every single pre-drilled hole. A 5/8" spade bit works perfect for doing the counter sink.

Side panels and console panels will also use LF blinds so be sure to account for them when ordering if your model has them.

120 degree counter sunk:

I use these rivets for attaching things like the stern light receptacle and other attachments that use a bevel head. The grip range all depends on what you're attaching. I have the range .251-.375.

Closed end blind rivet:

These are very useful as the body won't leak water around the mandrel and can be used on the transom to attach objects just don't use them or any other blind on the bottom or below the waterline where they can be struck, the heads are very weak compared to solids..

These rivets are specialized for using in an area where the closed end of the rivet won't allow water to leak through the body of the rivet. As said before don't use any blind rivets on the boat where the head might be impacted, only on the transom or above the waterline. It's recommended that 5200 also be used on these under the head and around the body for a water tight seal.

Tools used to set blinds are pretty simple, hand rivet sets and pneumatic gun sets. I recommend going for the latter, as your hand set cannot set the blinds as tight or as easily as the pneumatic set. I have a cheap one that has set 100's if not a thousand blind rivets and it's still going strong.

For your rivets, don't go looking for the cheapest brand you can find rather buy your rivets from a large well known trusted source. There is a difference between the quality of rivets you find at the big box store and the ones found at a reputable businesses and online retailers.

Have fun with you're riveting and always wear PPE, eye and ear protection. Invest is a good 3/16" and 5/32" pilot point titanium drill bit to remove the rivets and never use it on any sort of steel to make it dull.

Enjoy!

There are 2 types of rivets in 2 diameter sizes most commonly found on these boats. Solid rivets and blind rivets. Diameter sizes 3/16 in and 5/32 in. Some call blind rivets 'pop' rivets. From here on out I'll refer to them as blinds or solids. Each type of rivet be it either solid or blind come in several different types. I will try to demystify these subtle differences.

Solids:

The solid rivet is most commonly used to attach structural elements of the boat and of course is used to connect each of the separate panel seams of the boat. The most commonly used solids in your boat will be as follows.

Head: Brazier

Diameter: 3/16 in and 5/32 in

Length: Determined by the number of layers being fastened. Aluminum thickness common to the older riveted Starcraft boats.

Hull sides .080

Bottom and Ribs: .090

Transom .100

Gunnels and bow cover .065

I recommend having lengths of 3/8” for 2 layers and 7/16” for 3 layers on hand for your project. I personally would replace all structural solid rivets with 3/16 in.

Solid rivet material: Without getting into any arguments over metallurgy from those reading, here are the solids commonly found online in the correct diameter. 1100F which is pure soft aluminum and 2117T4 which is a strong alloy. The hull AL material is 5052 alloy. I would not recommend using 1100F pure soft AL on structural components such as the ribs.

Some tools of the trade when solid riveting.

Air Hammer

Rivet set 3/16" dia brazier head:

Bucking bar:

Clecos:

Very useful is holding pieces together that are to be fastened.

Blind Rivets:

Dome head blind:

The gunnels and bow cover are held on by 5/32" blinds in .126 - .187 grip range. The splashwell on my SS I used solids to attach it's splashwell and the consoles to the gunnels. If you use blinds I recommend 3/16" dia blinds for the splashwell and consoles and you may have to increase length in some cases to the next grip range. It never hurts to have multiple sizes as no two boat models are the exactly the same.

Large flange blind:

The decking is secured using the 3/16" LF blinds. Grip range is determined by how thick of plywood you'll be using for your decking.

1/2" and 5/8 in decking: 3/16 in diameter with a grip range of .625 - .875. If you're counter sinking the heads in order to lay carpet or vinyl deck covering over the installed decking then you'll want to drop to the next lower grip range (.501-.625) if using 1/2" plywood decking but that range listed above will work for 5/8 in ply.

3/4" plywood decking use the 3/16 in diameter with a .876-1.00 grip range. Also again if counter sinking the heads you could drop to the next lower grip range (.625-.875) For counter sinking I use a drill guide to get the exact depth desired on every single pre-drilled hole. A 5/8" spade bit works perfect for doing the counter sink.

Side panels and console panels will also use LF blinds so be sure to account for them when ordering if your model has them.

120 degree counter sunk:

I use these rivets for attaching things like the stern light receptacle and other attachments that use a bevel head. The grip range all depends on what you're attaching. I have the range .251-.375.

Closed end blind rivet:

These are very useful as the body won't leak water around the mandrel and can be used on the transom to attach objects just don't use them or any other blind on the bottom or below the waterline where they can be struck, the heads are very weak compared to solids..

These rivets are specialized for using in an area where the closed end of the rivet won't allow water to leak through the body of the rivet. As said before don't use any blind rivets on the boat where the head might be impacted, only on the transom or above the waterline. It's recommended that 5200 also be used on these under the head and around the body for a water tight seal.

Tools used to set blinds are pretty simple, hand rivet sets and pneumatic gun sets. I recommend going for the latter, as your hand set cannot set the blinds as tight or as easily as the pneumatic set. I have a cheap one that has set 100's if not a thousand blind rivets and it's still going strong.

For your rivets, don't go looking for the cheapest brand you can find rather buy your rivets from a large well known trusted source. There is a difference between the quality of rivets you find at the big box store and the ones found at a reputable businesses and online retailers.

Have fun with you're riveting and always wear PPE, eye and ear protection. Invest is a good 3/16" and 5/32" pilot point titanium drill bit to remove the rivets and never use it on any sort of steel to make it dull.

Enjoy!

Last edited: