1216bandit

Petty Officer 1st Class

- Joined

- Aug 18, 2008

- Messages

- 214

Two seasons back I ran the hose into the bilge on my 1993 22' islander, found leaking rivets and sealed them from the outside with 5300, which held up great till just recently. .The boat was water tight as a ducks rear end. I knew this was a temporary fix and was happy to get 2 seasons for so little work and time

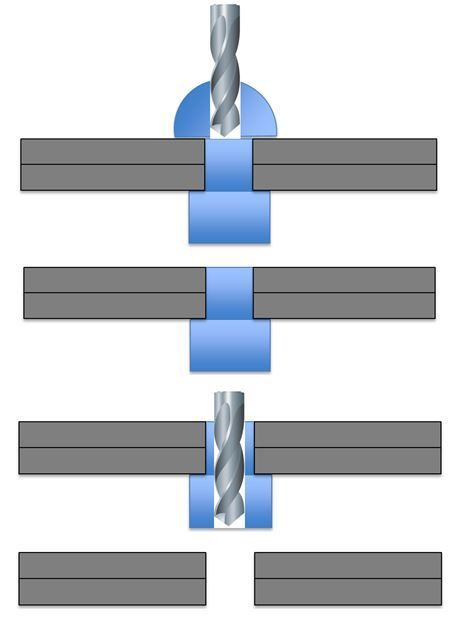

Anyhow, this fall I would like to do it properly and replace the leaking rivets and have a few questions for those that have done the job. All rivets will be replaced from outside.

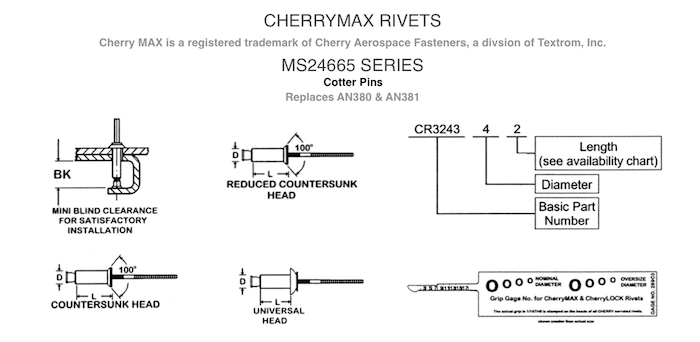

what blind rivet head most resembles the factory rivets?? No big deal just would like to do it this way if possible.

I read the rivets used are 3/16 but not sure of the length I would need??

Is a 3/16 drill bit or something else used to drill out the existing rivets?

Do you have to drill very deep into the rivet to be replaced before the head can be knocked off?

any tips or things to be careful of appreciated!

Thanx...Dan

Anyhow, this fall I would like to do it properly and replace the leaking rivets and have a few questions for those that have done the job. All rivets will be replaced from outside.

what blind rivet head most resembles the factory rivets?? No big deal just would like to do it this way if possible.

I read the rivets used are 3/16 but not sure of the length I would need??

Is a 3/16 drill bit or something else used to drill out the existing rivets?

Do you have to drill very deep into the rivet to be replaced before the head can be knocked off?

any tips or things to be careful of appreciated!

Thanx...Dan