toneeees

Administrator

- Joined

- Mar 15, 2011

- Messages

- 3,024

From Yamaha Marine

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Small (also known as 'portables') outboards - less than about 20-25 hp - are super simple to install, especially if the outboard is a tiller-steer, pull-start model. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Check out these tips but always refer to the engine manufacturer's owner's manual for instructions specific to your outboard. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]In the Middle

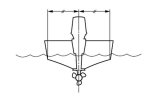

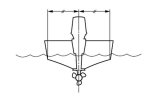

It's important that you mount the outboard on the centerline of the boat. Some transoms have a dot or discreet mark indicating the center, making the job a lot easier.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]However; if you're not so lucky, you'lll need to determine the transom's center by finding the center of the keel and drawing a line (perpendicular or square to the keel) straight up to the transom. Or drop a plumb bob from the transom to the keel's center, and mark the transom accordingly. There are several ways to find the center, but none is really difficult. If the outboard isn't in the center, the boat could be tough to steer and exhibit strange handling underway. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]If you're simply reinstalling the outboard on your boat, put the engine back where it was last year, and double-check that it's centered on the hull. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Turn the Screws

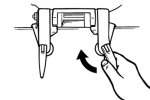

You've centered the outboard on the transom; now tighten the clamp screws to hold the engine on the transom.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Turn the clamp screws in evenly, so the clamping pressure is about the same for both clamp screws. Tighten them as much as you can; ideally the clamp screw handles can fold over and meet in the middle, so you can padlock them together. Locking the handles together prevents the clamp screws from working loose, and deters those who would be inclined to abscond with your outboard. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]If your outboard has an engine restraint cable attaching point, fasten a cable or chain from the outboard to the inside of the boat to avoid the outboard from parting company with your boat without notice. [/FONT]

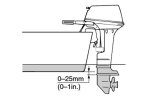

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Engine Height

With the clamp screws tight, and the engine positioned vertically, check the engine height in relation to the bottom of the boat by placing a straightedge along the keel to the outboard. The anti-ventilation plate should be even with the bottom of the hull or slightly (an inch or so) below the boat's bottom.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]When installing an outboard, you want it deep enough for the water pickups on the gearcase to draw in sufficient cooling water for the engine, and the propeller to stay hooked up with the water, but not so low in the water to create excess drag (resistance). [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]If the outboard is too high or too low, adjust its position accordingly, and re-tighten the clamp screws. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Additional Security

Once the outboard is positioned properly on the transom (centered and good engine height), and you are ready to permanently install the outboard, it's time to bolt the engine to the boat. If your outboard has provisions for bolts, the bolt holes should be located towards the bottom of the clamp bracket. We recommend marking the holes, and removing the engine before drilling through the transom. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]After you've drilled the bolt holes, blow out the shavings from the drill bit, and apply marine sealant to the inside of the holes. Re-mount the outboard, snug up the clamp screws (not extremely tight yet), then start the bolts through the transom and the clamp bracket (bolt head on the inside of the boat). [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Verify that the outboard is still centered on the transom, and the engine height is OK, then snug down the clamp screws to max tightness, and torque the transom bolts - without crushing the transom. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Use only the bolts that came with your engine, or stainless steel equivalents, including flat washers and lock washers, to keep everything in its place. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Check the clamp screws and transom bolts for tightness after running the boat a few hours (and periodically throughout the season) - re-torque (tighten) as necessary. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Finish the Job

The outboard is on the boat, now you'lll need to connect the fuel line, and do all of your pre-op checks (fuel filters, oil levels, propeller installation, etc.) before you hit the lake. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Don't forget the engine stop switch lanyard and required safety equipment as you're loading your gear.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif] [/FONT]

[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Then all you have to do is connect your portable fuel tank, pump the fuel line primer bulb a few times, pull the starter cord and have a safe, enjoyable boating season. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Small (also known as 'portables') outboards - less than about 20-25 hp - are super simple to install, especially if the outboard is a tiller-steer, pull-start model. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Check out these tips but always refer to the engine manufacturer's owner's manual for instructions specific to your outboard. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]In the Middle

It's important that you mount the outboard on the centerline of the boat. Some transoms have a dot or discreet mark indicating the center, making the job a lot easier.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]However; if you're not so lucky, you'lll need to determine the transom's center by finding the center of the keel and drawing a line (perpendicular or square to the keel) straight up to the transom. Or drop a plumb bob from the transom to the keel's center, and mark the transom accordingly. There are several ways to find the center, but none is really difficult. If the outboard isn't in the center, the boat could be tough to steer and exhibit strange handling underway. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]If you're simply reinstalling the outboard on your boat, put the engine back where it was last year, and double-check that it's centered on the hull. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Turn the Screws

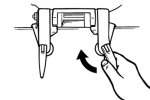

You've centered the outboard on the transom; now tighten the clamp screws to hold the engine on the transom.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Turn the clamp screws in evenly, so the clamping pressure is about the same for both clamp screws. Tighten them as much as you can; ideally the clamp screw handles can fold over and meet in the middle, so you can padlock them together. Locking the handles together prevents the clamp screws from working loose, and deters those who would be inclined to abscond with your outboard. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]If your outboard has an engine restraint cable attaching point, fasten a cable or chain from the outboard to the inside of the boat to avoid the outboard from parting company with your boat without notice. [/FONT]

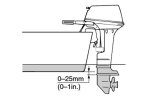

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Engine Height

With the clamp screws tight, and the engine positioned vertically, check the engine height in relation to the bottom of the boat by placing a straightedge along the keel to the outboard. The anti-ventilation plate should be even with the bottom of the hull or slightly (an inch or so) below the boat's bottom.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]When installing an outboard, you want it deep enough for the water pickups on the gearcase to draw in sufficient cooling water for the engine, and the propeller to stay hooked up with the water, but not so low in the water to create excess drag (resistance). [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]If the outboard is too high or too low, adjust its position accordingly, and re-tighten the clamp screws. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Additional Security

Once the outboard is positioned properly on the transom (centered and good engine height), and you are ready to permanently install the outboard, it's time to bolt the engine to the boat. If your outboard has provisions for bolts, the bolt holes should be located towards the bottom of the clamp bracket. We recommend marking the holes, and removing the engine before drilling through the transom. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]After you've drilled the bolt holes, blow out the shavings from the drill bit, and apply marine sealant to the inside of the holes. Re-mount the outboard, snug up the clamp screws (not extremely tight yet), then start the bolts through the transom and the clamp bracket (bolt head on the inside of the boat). [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Verify that the outboard is still centered on the transom, and the engine height is OK, then snug down the clamp screws to max tightness, and torque the transom bolts - without crushing the transom. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Use only the bolts that came with your engine, or stainless steel equivalents, including flat washers and lock washers, to keep everything in its place. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Check the clamp screws and transom bolts for tightness after running the boat a few hours (and periodically throughout the season) - re-torque (tighten) as necessary. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Finish the Job

The outboard is on the boat, now you'lll need to connect the fuel line, and do all of your pre-op checks (fuel filters, oil levels, propeller installation, etc.) before you hit the lake. [/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Don't forget the engine stop switch lanyard and required safety equipment as you're loading your gear.[/FONT]

[FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]

[/FONT]

[/FONT][FONT=Trebuchet MS, Lucida Grande, Arial, sans-serif]Then all you have to do is connect your portable fuel tank, pump the fuel line primer bulb a few times, pull the starter cord and have a safe, enjoyable boating season. [/FONT]