Metaphorically speaking, all these details are the floor, ceiling, and walls; and I'm getting further from the door... with investments of time and money.

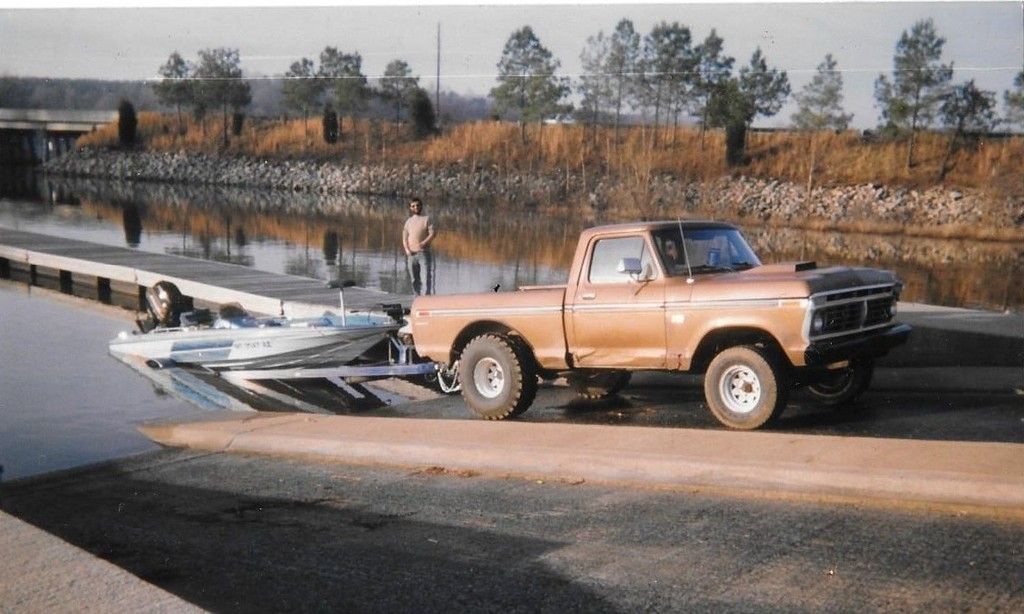

While waiting on the motor work, I installed new big block coil springs up front on 2" blocks for extra lift. Already had 31" tires all around, but bought two 38" Kelly Springfield 12ply directional mudders for the rear. Those tires had a 15" foot print.

A 9" Auburn Gear 4.86ltd slip new for $900. Did my own body lift graduated from stern to bow lol, to keep it looking level and so my head wasn't looking at the dirt so much!!! haahaaaaa Carpeted and insulated entire cab for sound deadening and installed seats/safety belts, console etc from an '88 Eddie Bauer Bronco. The body was light because much of it had rusted away! I never thought it was much for looks other than a bit odd!!

but everybody sure liked riding in it!

THE HEADERS!! I studied that problem for all of a minute and came up with "I can grind the bellhousing", which I didn't do. Figured it was extra thick from the factory in case the flywheel came unglued. I needed 1/2" for 1/8th clearance - took 1/2" plate longer than the head and had him match ports and bolt holes for headers and intake manifold. THAT took awhile!!

But I had all these other things to do anyway. Next!! When I stabbed the tranny, the input shaft didn't quite make it to the splines in the clutch! hmmmm Took the old crankshaft and supersized flywheel and had the end of the cs cut off and pinned to flywheel, then checked for balance. Made clutch linkages and make sure they'd work hassle free. I used the V8 motor mount pedestal holes to set everything back further for a tad better weight distribution - seemed to have made a big difference in handling? Rancho shocks and heavier springs made it stouter too... Complete r&r on the brakes and system.

Finally, a break in his racing schedule and I got the plate back for $200... which I thought was cheap considering the precision involved. I was busy before but busier now getting everything just so.

I was doing all of this by myself at home while working as a maintenance mechanic at a large factory. On call 7nights out of every 14, maintaining household (laundry, cleaning, cooking, etc), not married which is not all good nor all bad, it just is.

I like building things and being creative, which means, I really enjoyed this project; but....... that dang corner I didn't see coming because.... I just didn't see it comin!! Ain't that how it always is

I'll tell ya next..... and if you haven't had a good laugh in awhile, have 911 on speed dial!!!

:facepalm: :lol: <<<my typical responses in order, after realizing said occurrence!

:facepalm: :lol: <<<my typical responses in order, after realizing said occurrence!