My local boating club has a 800 Mt rowing water course, if in need to fine tune engine transom height for a spot on perfect match after initial setup, we use this nice facility. Most tested sibs were wooden, alum, flat air decks versions, tiller driven engines and manual trim up to 30 HP engines. All sib/ribs were water tested under these strict lab conditions :

-Flat calm, glassy no wind water environment.

-Sib tubes & keel, min 3.0 PSI with gauge.

-Tiller driven engine trimmed to 90 angle.

-Mostly S-L 18 HP Tohatsu engines.

-Engine and prop in top working condition,

- Driver/spotter at throttle, balancer mate up front.

-Fresh high octane fuel.

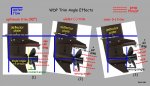

- As no one engine manufacturer has provided a real clue at which LU height must water flow pass at speed for best combo water performance, will stick to Yam statement, moons back under trial and error have dialed the sweet engine/transom spot, is located between upper water deflector plate (WDP) and lower AV plate. Right in middle you have a sharp edge in which water flow is evenly cut achieving the least water drag resistance on the entire LU.

It's impossible to get rid of the water drag resistance as water is 100 times denser than air, but could be minimized while passing through that sharp large edge.