I have a 2006 Yamaha 2-Stroke 50TLR outboard that was giving me intermittent loss of power and appearing to go into limp mode. Now it’s 100% under full load. Will start up every time and idle great. I can briefly throttle up to 3,000 RPM in neutral with no issues, but when in the water under full load it only now gets up to 1,200 RPM’s.

Below are all the items I validated as good, replaced, or rebuilt:

Below are all the items I validated as good, replaced, or rebuilt:

- Removed all gas from the built-in tank and replaced with recreational gas.

- Replaced the primer bulb and secondary downstream gas hose.

- Removed the bowel filter and cleaned (Some minor debris)

- Replaced the gas pump with a new unit.

- Removed all engine side gas lines, inspected visually, and blew out each hose.

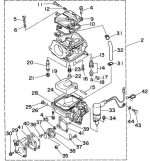

- Removed, soaked all three carburetor pieces, rodded out every orifice with appropriate copper wire, and rebuilt with new gasket kit to OEM specifications.

- Warm up heat sensor checks good and operates.

- Water overheat sensor checks good and operates.

- Oil injector float sensor checks good and operates.

- Alarm that operates the two limp mode sensors works, but never comes on.

- New spark plugs.

- New spark plug boots and springs.

- All control rod linkages set to service manual specifications.

- All electrical connects are seated and look good.

- Getting good spark on all three cylinders that will jump a ¾” gap while idling.

- Most ignition components ohm out to OEM specifications.

- Disconnected the pink wire from the CDI unit under full load with no change. After rebuilding the carburetors and while under load squeezed the primer bulb repeatably with no change to the RPM’s.

- I’m leaning that the CDI unit (#63D-03) is faulty and not advancing. Don’t have a CDI tester and most local dealers don’t either. New unit $552 and want a second opinion before spending the money.

- The engine has 670 hours and I’m the third owner with compression readings on all three cylinders is at 110 PSI from OEM stating 122 PSI minimum. Online some boat engine forms say the engine can still run OK with 100 PSI compression. I know this is low, but hoping to get more time out of this motor before rebuilding or replacing it. Head bolts are tight and I can’t see any gasket leaks, feel the compression loss is piston ring related.

- Bottom line Is this low compression the cause of the loss of power under load? If not, I will procure the new CDI unit as everything else has been exhausted to be the cause of this issue.