What are the thoughts on keeping the rainwater out of the boat when sitting with mooring cover installed? A full storage cover with sides that drape over the hull would sort that out of course, but I'm wondering about successful diversion of rainwater with a mooring cover alone. On my hull, the tops of the gunnels are flat, with an extruded aluminum rub-rail trim on both inside and outside edge. The typical mooring cover terminates on the flat, dumping all that rainwater on the gunnel. The rub-rail trims now effectively make a 'canal' for the water to flow down along the gunnel top, until it leaks over the sides, or hits the transom corner cap at the back. I'm thinking the outer rubrail trim doesn't need sealant, as any water that migrates under will just drip down the outside of the hull where it belongs. The other areas are where I have some questions:

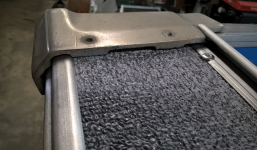

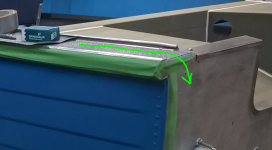

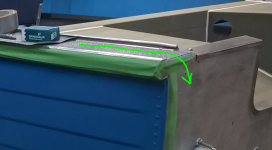

1.) The pic here shows the inner and outer rubrail trim extrusions. Water will flow aft following green arrow. Note that the same profile runs all the way to the transom, but isn't installed aft of the console in this pic. I simply riveted this trim down to the top of the gunnel without sealant. There was no sign of sealant used prior, but I'm thinking perhaps I should remove and reinstall with a strip of butyl, or polyurethane sealant to keep the gunnel water from leaking underneath, and down the inner sides of the gunnels in the red areas shown below. Thoughts?

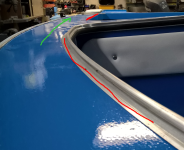

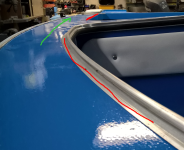

2.) How is the water flow handled when it reaches the transom corner cap? I'm thinking that area should be sealed well to either prevent water intrusion below the cap, or alternatively forced to make its way to the aft edge of the transom, where it an spill overboard. I've used Nautolex on the gunnel tops up to about midships, and wish I'd left it run just a bit long so it could hang over the transom at the back, allowing water to flow overboard under the transom cap. Port side shown in the pic isn't bad, but the other side is trimmed a bit short.

Your typical fiberglass hull has sloped sides, so the mooring cover automatically discharges that water overboard. See random pic below. It's a rainy day, so as I look out my office, my subconscious is thinking about this boat project and keeping my hard work dry!

1.) The pic here shows the inner and outer rubrail trim extrusions. Water will flow aft following green arrow. Note that the same profile runs all the way to the transom, but isn't installed aft of the console in this pic. I simply riveted this trim down to the top of the gunnel without sealant. There was no sign of sealant used prior, but I'm thinking perhaps I should remove and reinstall with a strip of butyl, or polyurethane sealant to keep the gunnel water from leaking underneath, and down the inner sides of the gunnels in the red areas shown below. Thoughts?

2.) How is the water flow handled when it reaches the transom corner cap? I'm thinking that area should be sealed well to either prevent water intrusion below the cap, or alternatively forced to make its way to the aft edge of the transom, where it an spill overboard. I've used Nautolex on the gunnel tops up to about midships, and wish I'd left it run just a bit long so it could hang over the transom at the back, allowing water to flow overboard under the transom cap. Port side shown in the pic isn't bad, but the other side is trimmed a bit short.

Your typical fiberglass hull has sloped sides, so the mooring cover automatically discharges that water overboard. See random pic below. It's a rainy day, so as I look out my office, my subconscious is thinking about this boat project and keeping my hard work dry!