Plandeck

Petty Officer 2nd Class

- Joined

- Jul 8, 2012

- Messages

- 115

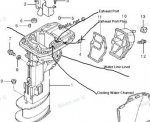

Anybody know why it would be wrong to exhaust idle gas from my 8h 2008 4 stroke Nissan outboard through the exhaust plug instead of the regular gas/water mix idle port? Too hot? The idle exhaust must run through 8' of 1/2-inch exhaust hose. (See attached drawing)

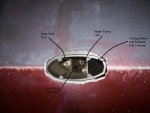

Why this? I reinstalled the old 8hp outboard which hung off of the transom into the hold, dropping the prop shaft through the bottom of the boat. So now it is install as if it were an inboard. (see photo) The concern is, dropping it into the hold lowered the power head relative to the water line significantly. The lower unit is caulked where it passes through the hull, but water will obviously enter up the lower unit past the hull. It will enter up to a level somewhere in the middle of the water/gas idle port. Thus it's my preference to exhaust the idel gas a few inches higher through the exhaust plug before it mixes with the cooling water as shown on the drawing.

Any reason why this should not be done?

Why this? I reinstalled the old 8hp outboard which hung off of the transom into the hold, dropping the prop shaft through the bottom of the boat. So now it is install as if it were an inboard. (see photo) The concern is, dropping it into the hold lowered the power head relative to the water line significantly. The lower unit is caulked where it passes through the hull, but water will obviously enter up the lower unit past the hull. It will enter up to a level somewhere in the middle of the water/gas idle port. Thus it's my preference to exhaust the idel gas a few inches higher through the exhaust plug before it mixes with the cooling water as shown on the drawing.

Any reason why this should not be done?