OK, so through a mix of research and ciphering I got this figured out and in an effort to close this thread and help some other poor soul I'll document my adventures...

I am going to post this in several posts rather than one big one to make sure the dog does not eat my homework before I hit the final POST button.

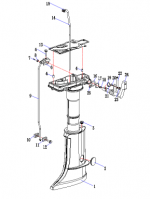

First of all the motor is a 2014 Yamaha Outboard 6hp F6SMHA. When changing the impellor the water tube broke. This was no doubt due to corrosion on the copper tube from leaving the bottom end of the motor in salt water as is required at the Key West dingy dock. The water tube part is #6EE-G4360-00-00 and includes the rubber bushing that holds the tube in place just under the power head. To replace this tube you must pull the powerhead. The manual will have you disconnect a lot of parts but I chose to remove only as much as I saw was needed, mainly the fuel line and fuel tank as well as the pull-start. Other than that, there are nine bolts, 4 long and five shorter. Note which bolts go where.

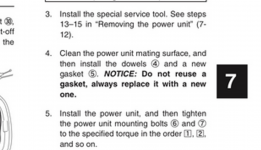

.

The three bolts with the large washers are from the lower cowling and did not need to be removed so I replaced them before replacing the powerhead. With the bolts removed the powerhead was stuck fairly tight to the gasket. Gentle persuasion with a block of wood under the flywheel and taps from a hammer eventually freed the powerhead after which I simply tilted it to one side and secured it as seen in the picture.

Continued....