IHDiesel73L

Seaman

- Joined

- Aug 2, 2010

- Messages

- 70

I've settled on building a mud motor to have in addition to my small outboard for times when I want to run shallow. I've seen a lot of different designs that use a universal joint with the motor sitting flat and the driveline bent into the water, but I saw this design and really thought it was much cleaner and simpler:

It's made by a company called Backwater and retails for about $2500 With a free engine (courtesy of my dad's shop) and heavily discounted materials (I have a relative in the supplier biz) I should be able to build my "Poor Man's Backwater Longtail" for about $500...

With a free engine (courtesy of my dad's shop) and heavily discounted materials (I have a relative in the supplier biz) I should be able to build my "Poor Man's Backwater Longtail" for about $500...

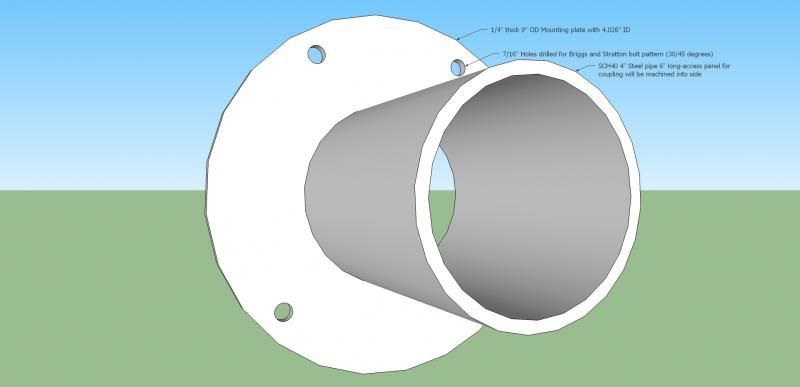

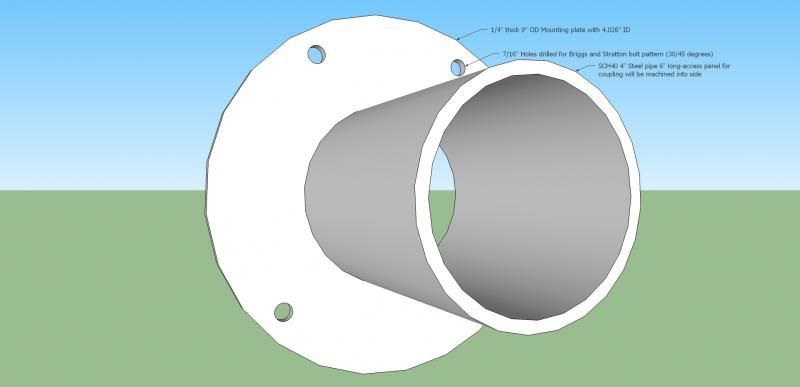

I'd start with a steel ring fabricated from 1/4" plate and drilled for the outermost holes on Briggs and Stratton horizontal shaft. These take the largest (7/16" bolts) and I think have the mounting holes set wide is probably better for strength. A 6" section of SCH40 black steel pipe would be welded in the center, which will serve as the housing for the coupling. An access hole will be machined into the side (I couldn't figure out how to draw it in Sketchup) so that a removable cover can be fitted. This way the roller chain coupling ( McMaster-Carr ) can be accessed and I can pack the housing with grease:

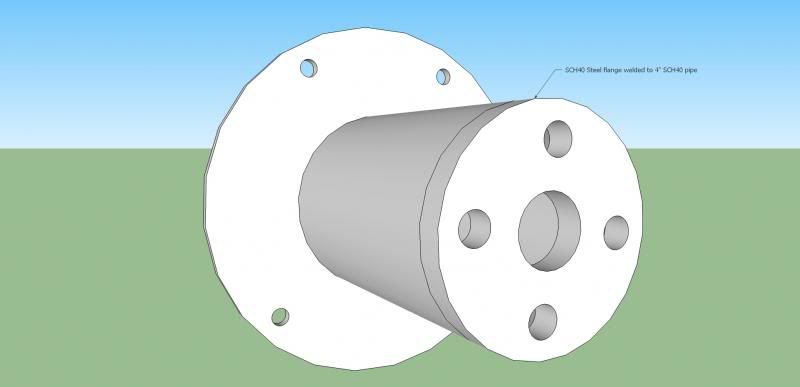

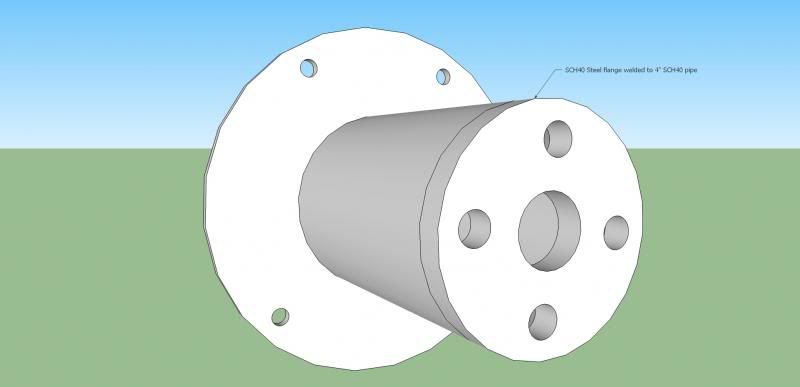

Next, a SCH40 Black steel flange would be welded onto the end of the pipe with the flat side facing out. Stainless steel studs will be fitted from the backside facing out so that the flange connected to the driveshaft housing can be fitted over top and bolted down with stainless nylock nuts and lockwashers:

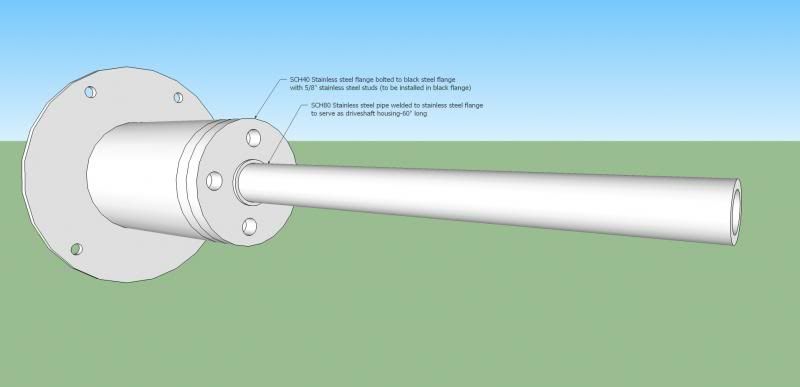

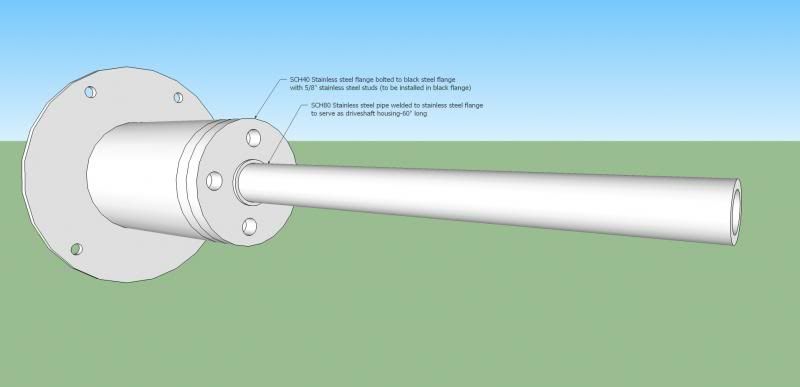

Finally, a SCH40 Stainless steel flange would be welded to a length of SCH80 (Because of the smaller ID) stainless steel pipe which would form the driveshaft housing. The full pipe will be 60" long-I just kept it short so it would fit in the picture. The pipe would protrude slightly through the opposite side of the flange into the black steel flange in order to help locate and center it. Even then, the alignment will be hard to get perfect, which is why I opted for the roller chain coupling as they tolerate a little misalignment pretty well.:

Let me know what you all think-the stainless might seem like overkill, but I'm getting a deep discount on the materials. I guess I could build one out of all black pipe first for really cheap and see how it like though? Eveything else about the build would be pretty conventional-three bushings, one top, one middle, one bottom, an automatic grease cup for lubrication, and a seal/retainer cap at the bottom. The shaft will be stainless as well. The boat will never see salt or probably even brackish water, but I figure it will be a good idea in the long run.

It's made by a company called Backwater and retails for about $2500

I'd start with a steel ring fabricated from 1/4" plate and drilled for the outermost holes on Briggs and Stratton horizontal shaft. These take the largest (7/16" bolts) and I think have the mounting holes set wide is probably better for strength. A 6" section of SCH40 black steel pipe would be welded in the center, which will serve as the housing for the coupling. An access hole will be machined into the side (I couldn't figure out how to draw it in Sketchup) so that a removable cover can be fitted. This way the roller chain coupling ( McMaster-Carr ) can be accessed and I can pack the housing with grease:

Next, a SCH40 Black steel flange would be welded onto the end of the pipe with the flat side facing out. Stainless steel studs will be fitted from the backside facing out so that the flange connected to the driveshaft housing can be fitted over top and bolted down with stainless nylock nuts and lockwashers:

Finally, a SCH40 Stainless steel flange would be welded to a length of SCH80 (Because of the smaller ID) stainless steel pipe which would form the driveshaft housing. The full pipe will be 60" long-I just kept it short so it would fit in the picture. The pipe would protrude slightly through the opposite side of the flange into the black steel flange in order to help locate and center it. Even then, the alignment will be hard to get perfect, which is why I opted for the roller chain coupling as they tolerate a little misalignment pretty well.:

Let me know what you all think-the stainless might seem like overkill, but I'm getting a deep discount on the materials. I guess I could build one out of all black pipe first for really cheap and see how it like though? Eveything else about the build would be pretty conventional-three bushings, one top, one middle, one bottom, an automatic grease cup for lubrication, and a seal/retainer cap at the bottom. The shaft will be stainless as well. The boat will never see salt or probably even brackish water, but I figure it will be a good idea in the long run.

Last edited: